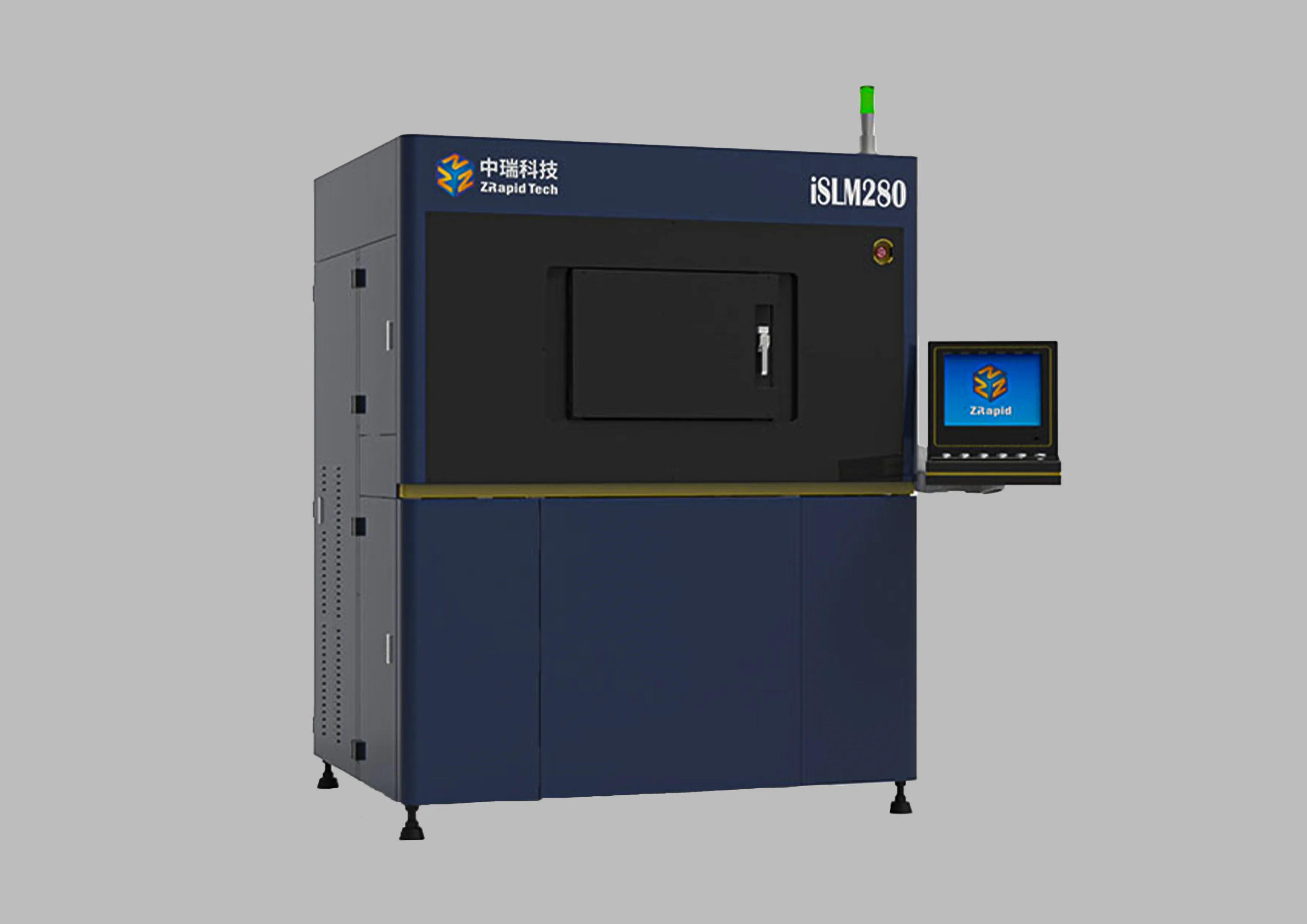

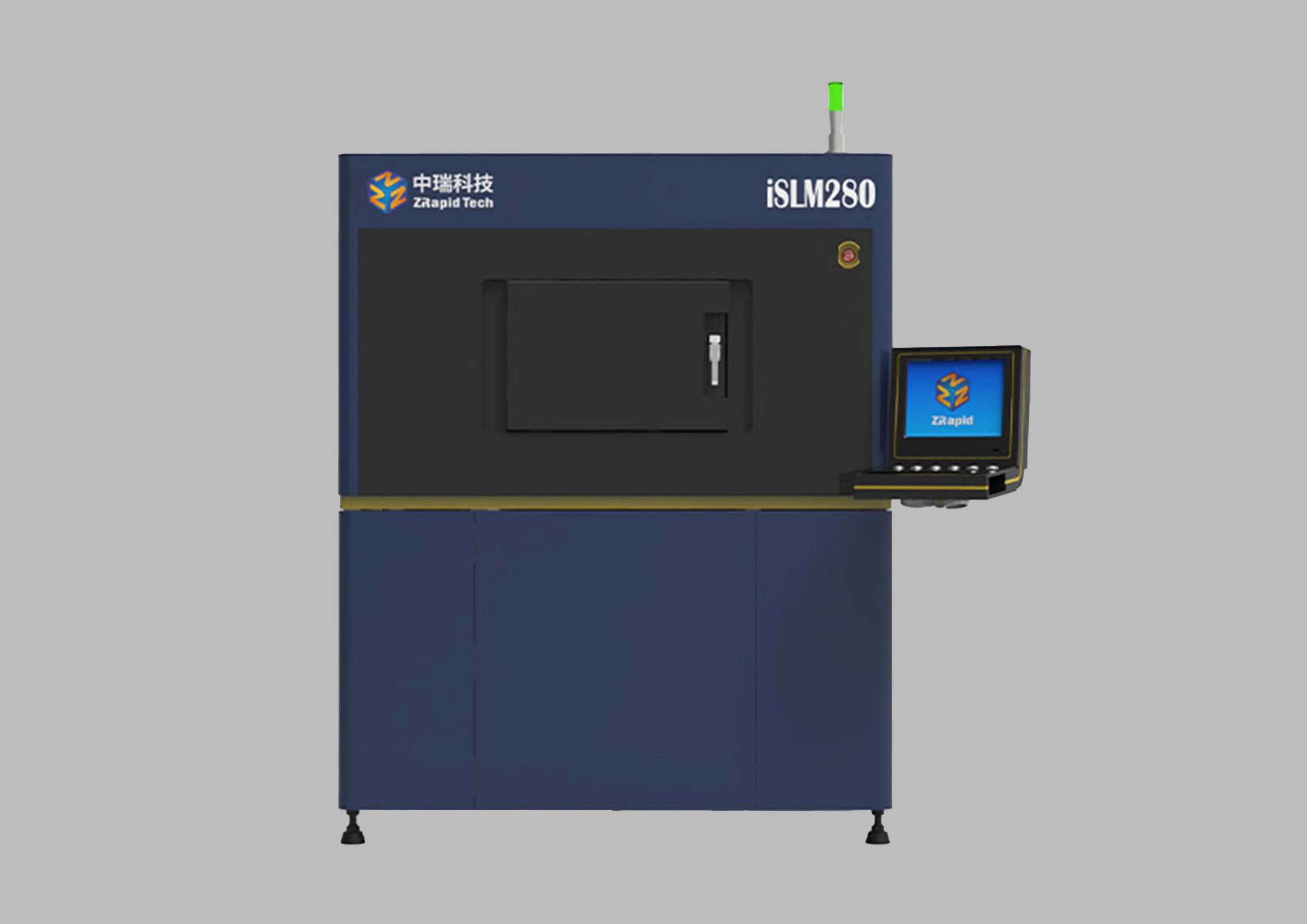

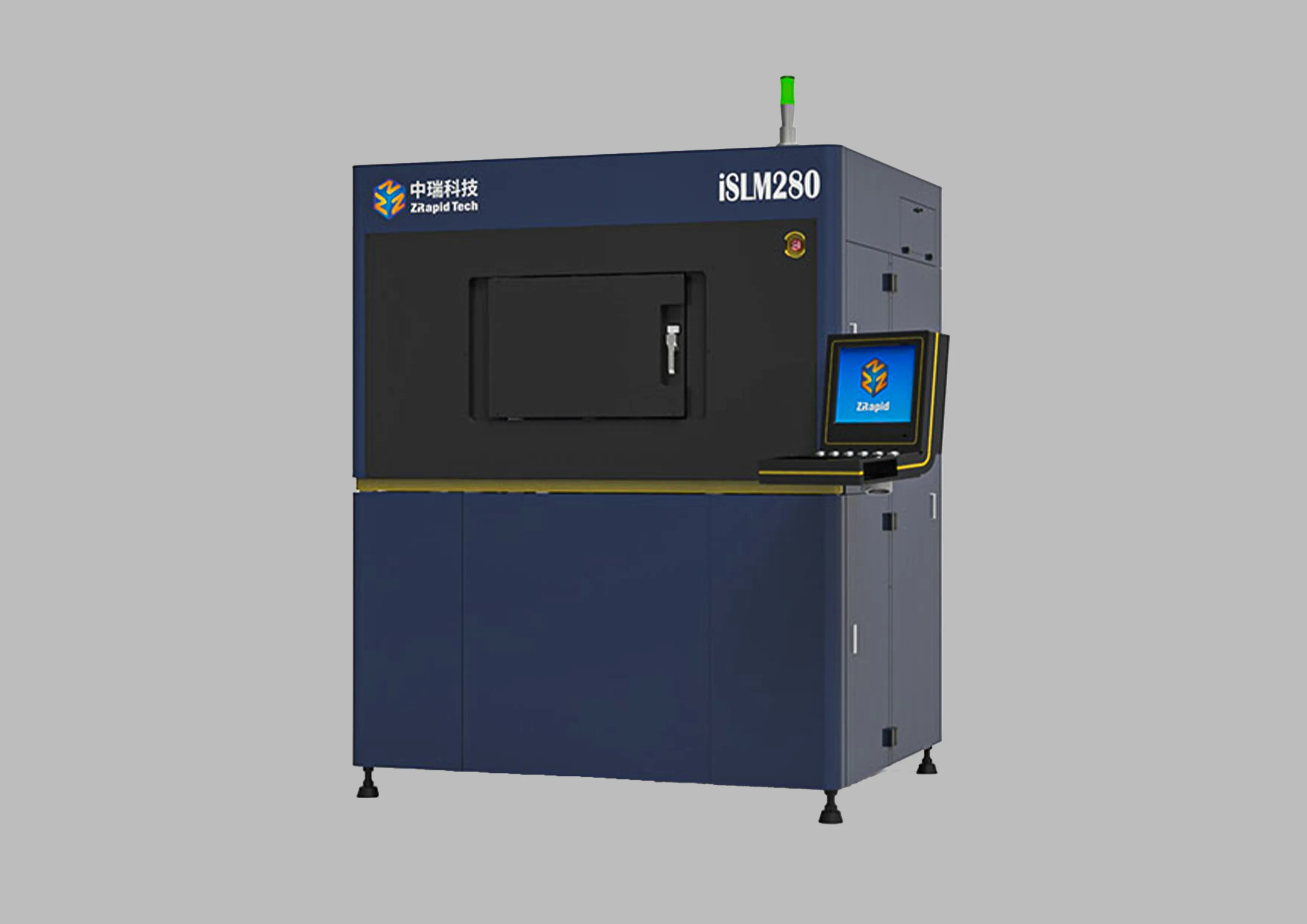

The SLM 280 3D printer utilizes Selective Laser Melting (SLM) technology, a process that involves melting metal powders and solidifying them layer by layer to create three-dimensional parts. Within the build chamber, a metal powder layer is evenly spread by a roller. A high-powered laser selectively fuses the powder by tracing the part's cross-section on the powder bed's surface. Subsequently, a new layer of material is applied for the next stage. To prevent unwanted reactions between the metal powder and oxygen at high temperatures, the entire process takes place in a controlled environment, typically within a high vacuum or a chamber filled with protective gas.

| LASER SYSTEM |

Type: Fiber laser Wavelength: 1064nm Power: 500W |

|---|---|

| RECOATING SYSTEM |

Process: bi-directional scraper paving Normal Build: 0.05mm Quick Build: 0.05~0.15mm Precision Build: 0.02~0.05mm |

| OPTICAL & SCANNING |

Beam (diameter@1/e2): 0.06~0.20mm Scanning Galvanometer: High Speed Scanning Galvanometer Parts Scanning Speed: 1.0~4.0m/s (recommended) Blank Jumping Speed: 10.0m/s (recommended) Reference Building Speed: 4~20cm³/h |

| SHIELD SYSTEM |

Protective gas: N2 / Ar(Active metal materials must be protected with Ar) Flow Control: 0~3 L/min intellient adjustment dust extraction control: High efficiency Protection recycling system |

| BUILD VAT |

Volume: Approx. 25L XY Platform: 280mm(X) × 280mm(Y) (Screw hole, rounded, etc. are not calculated) Z Axis; 380mm(Including substrate thickness) Max Weight: 70kg Type: Precision resistor heater Materials: Stainless Steel / Die Steel / Titanium Alloy / Aluminium Alloy / Co-Cr Alloy / Nickel Alloy / Cuprum etc. |

| SOFTWARE |

Operating System: Windows 10Pro Network: Ethernet, TCP/IP, IEEE802.3 Control Software: iSLM(Presto SLM) Date Preparation Software: 3dLayer Data Interface: CLI file, SLC file, STL file |

| INSTALLATION CONDITION |

Power: 220V(±10%) AC 50/60Hz, single-phase, 5/20A Ambient Temperature: 20-26ºC Relative Humidity: Less than 40%, non-condensing Size: 1.75m(W)×1.40m(D)2.20m(H)(Operating computer is not included) Weight: Approx. 1800kg |

| WARRANTY |

Laser: 5000 hours or 12 months (whichever comes first) Main Machine: Two (2) from installation date |