3D Model Preparation:

A digital 3D model is created in CAD software or sourced from a library. The file is exported in STL/OBJ format for slicing.

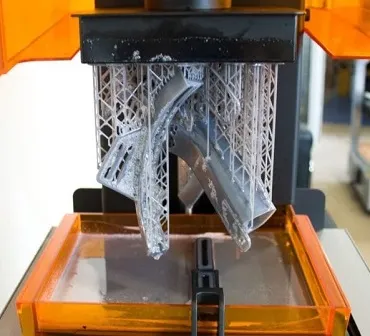

Digital Light Processing (DLP) is an advanced resin-based 3D printing technology known for its exceptional speed, fine detail, and smooth surface finish. It uses a digital light projector to cure photopolymer resin layer-by-layer, enabling the creation of highly accurate and detailed components suitable for prototyping, dental models, jewelry casting patterns, and functional engineering parts (with engineering-grade resins).

DLP 3D printing excels in creating fine, intricate geometries that are nearly impossible to achieve with traditional methods or filament-based 3D printing. With resolutions as fine as 25–50 microns, designers can achieve smooth surfaces, crisp edges, and intricate internal details.