• Rapid fabrication of custom parts and prototypes.

• Eliminates additional tooling, reducing lead times.

• Enables high-quality, customized production.

• Offers greater flexibility and design freedom.

• Reduces material waste, improving sustainability.

• Lowers production costs and boosts efficiency.

• Production of industrial parts and custom components.

• Creation of functional 1:1 - scale prototypes.

• Manufacturing of tooling, jigs, and fixtures.

• Development of conceptual and visual models.

• On-demand spare parts for machinery.

• Fabrication of small, intricate mechanical parts.

• Making training aids for industrial education and safety.

• Rapid prototyping of plastic products for fast testing.

• Cost-effective production without traditional molds.

• Faster design iterations and time-to-market.

• On-demand spare parts for machinery.

• Easy modifications before mass production.

• Real material testing for better accuracy.

• Customized plastic packaging for various products.

• Unique shapes and creative packaging designs.

• Branded packaging with logos and visuals.

• Prototype packaging for marketing and approval.

• Enhanced consumer appeal and shelf visibility.

• Enables innovative and multi-functional designs.

• Reduces cost by eliminating multiple component fabrication.

• Accelerates product development and design iterations.

• Offers high precision for complex electronic geometries.

• Minimizes waste and scrap through accurate production.

• Allows quick production changes and flexible workflows.

• Production of custom circuit boards (PCBs).

• Fabrication of antennas, sensors, and connectors.

• Creation of wearables, smartphones, and drones.

• Rapid prototyping of silicone membrane buttons.

• Development of custom shielding and enclosures.

• Mold making and modification for injection molding.

• Enables production of lighter, stronger, complex parts.

• Reduces prototyping time with rapid design testing.

• Lowers R&D and tooling costs for new models.

• Improves fuel efficiency with lightweight components.

• Ensures high reliability and product quality.

• Streamlines automotive design and manufacturing process.

• Custom brackets, mounts, and interior parts.

• Components for lighting systems and wheels.

• Exterior parts like panels, spoilers, and tailpipes.

• Functional engine and transmission components.

• Valve seals, air scoops, and exhaust systems.

• Production of car bodies, axles, tools, and keys.

• Enables fast production of complex medical devices.

• Reduces manufacturing costs and time significantly.

• Improves healthcare access in remote and developing areas.

• Allows patient-specific organ models for education and surgical planning.

• Supports custom implants, prosthetics, and tools tailored to individual patients.

• Production of custom prosthetic limbs and body parts.

• Fabrication of dental implants and crowns.

• Creation of customized wheelchairs and orthotic devices.

• Manufacturing of surgical instruments and tools.

• Development of medical training models and organ replicas.

• Creation of scaffolds for tissue engineering.

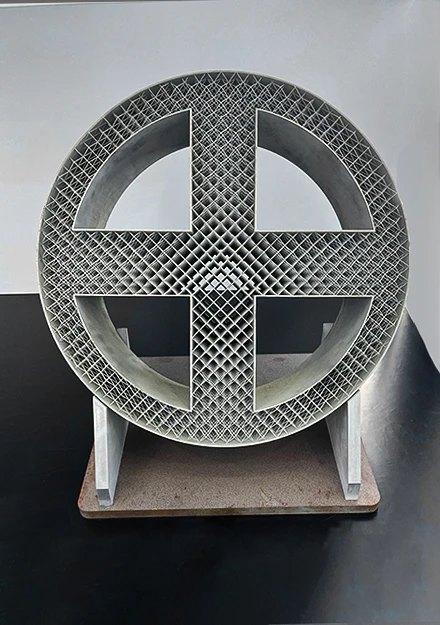

• Enables on-demand production of lightweight, complex parts.

• Supports customized components for new and existing aircraft.

• Reduces production costs by eliminating tooling needs.

• Uses durable, high-performance materials for critical parts.

• Lowers fuel consumption by reducing aircraft weight.

• Enhances design flexibility, sustainability, and performance.

• Manufacturing of aerospace tooling parts.

• Production of aircraft interiors and seating components.

• Creation of fuselage, wings, and empennage structures

• Printing of propellers, blades, and vanes.

• Fabrication of landing gear and rocket engine parts.

• Development of custom satellite components.

• Reduces manufacturing costs and material waste.

• Enables fabrication of complex parts using robust materials.

• Allows rapid prototyping and early testing of new designs.

• Supports next-gen defence tech like drones and autonomous systems.

• Produces lighter, compact components for military vehicles and aircraft.

• Enhances battlefield prosthetics and medical equipment for soldiers.

• Production of marine hardware and body armour.

• Manufacturing of drone components and vehicle parts.

• Fabrication of firearms, ammunition, and weapon systems.

• Creation of helmets, shields, and tactical gear.

• Custom medical implants and prosthetic limbs.

• Development of robots and defense automation tools.

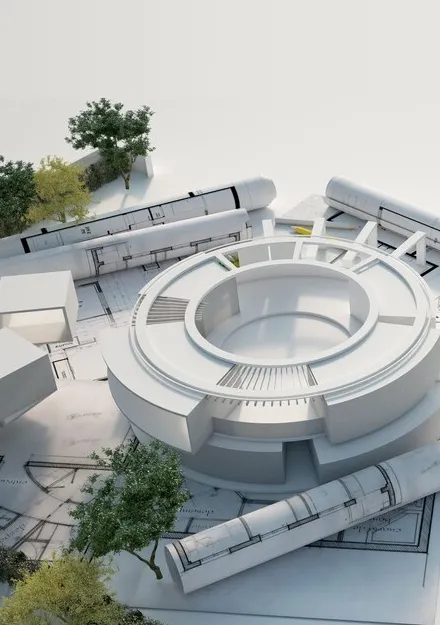

• Accelerates complex architectural design and construction.

• Enables precise creation of intricate geometries at lower cost.

• Reduces construction waste by printing large sections as single units.

• Helps architects visualize concepts through detailed physical models.

• Supports the design of organic shapes, textures, and curves.

• Aids in material selection by testing design compatibility effectively.

• Creation of physical models and architectural prototypes.

• Fabrication of molds and forms for precast concrete elements.

• Production of custom fixtures and decorative wall panels.

• Design of furniture and scale models of buildings.

• Development of recyclable building components like walls and roofs.

• Manufacturing of doors, window frames, and ornamental accents.

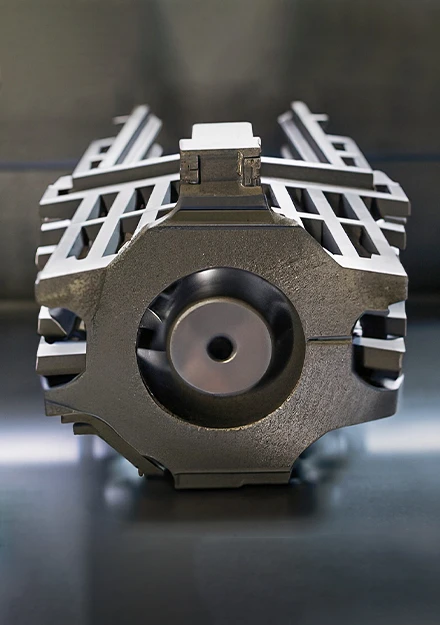

• Reduces costs by creating complex, customized parts.

• Optimizes designs for improved efficiency and performance.

• Produces metal parts like valves, nozzles, and casings.

• Enables rapid prototyping of parts with complex shapes.

• Streamlines supply chain with on-demand part production.

• Shortens lead times, reducing downtime and accelerating operations.

• Creation of parts for drilling and extraction equipment.

• Manufacturing of drill bits and valves.

• Production of pipeline components and safety parts.

• Fabrication of chemical tanks and welding jigs.