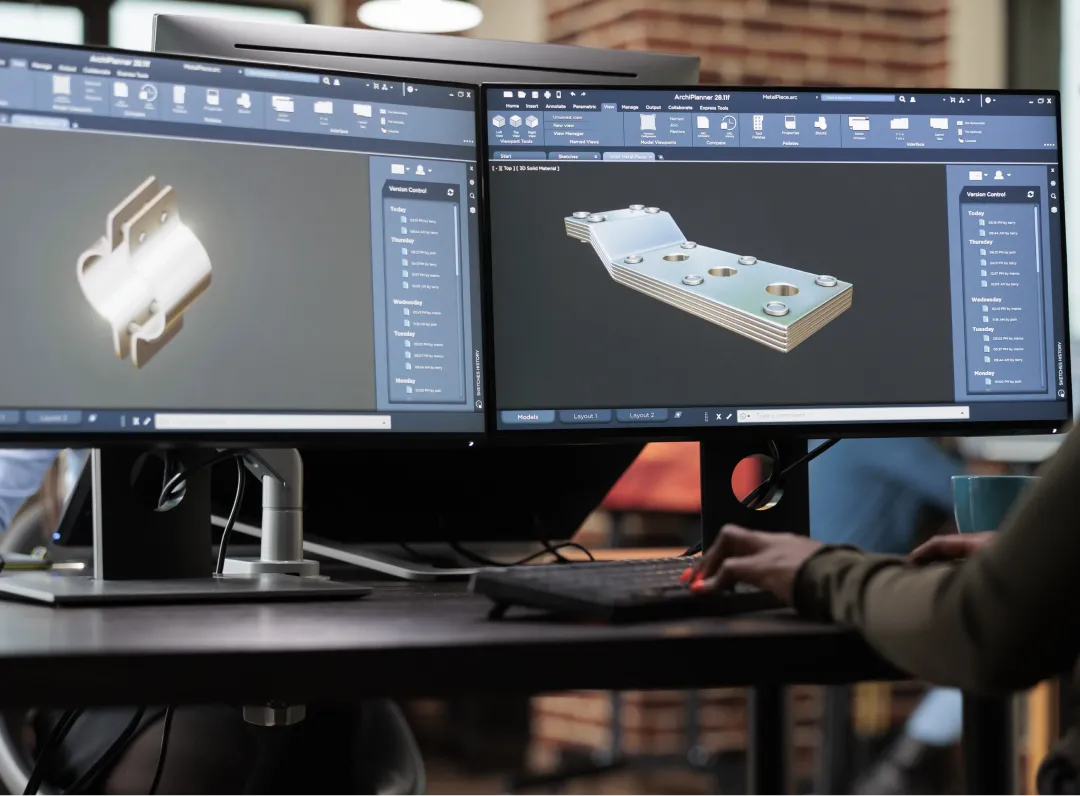

Heat Treatment

Heat treatment is a controlled process used to modify the physical and mechanical properties

of materials, primarily metals and alloys, through carefully controlled heating, soaking,

and cooling. By subjecting the material to specific temperature ranges and cooling rates,

heat treatment can enhance desirable properties such as hardness, strength, toughness, and

ductility.

It involves various techniques such as annealing, hardening, tempering, and case hardening.

Annealing relieves internal stresses and improves machinability and ductility. Hardening

increases hardness and strength by rapid cooling, followed by tempering to reduce

brittleness and enhance toughness. Tempering further modifies the material's properties by

reheating and controlled cooling.

Case hardening creates a hard outer layer while maintaining a softer, more ductile core.

Heat treatment is an essential process in manufacturing and metalworking industries,

allowing materials to be tailored to specific applications, improve performance, and achieve

desired characteristics.