CNC Machining

Computer Numerical Control (CNC) machining is a technology that uses computer-controlled

machines to create parts and products from various materials. CNC stands for computer

numerical control, which means that the machines follow a set of instructions or code that

tells them how to move and cut the material. CNC machining can produce parts and products

with high accuracy, speed, flexibility, and quality, making it a superior method to

traditional machining methods. In this article, we will explain how CNC machining works,

what are its advantages, and how Vexma Technologies can help you with your CNC machining

needs.

How CNC Machining Works

CNC machining involves four main steps: Designing, Programming, Setting up, and

Machining. Here is a brief overview of each step:

Designing

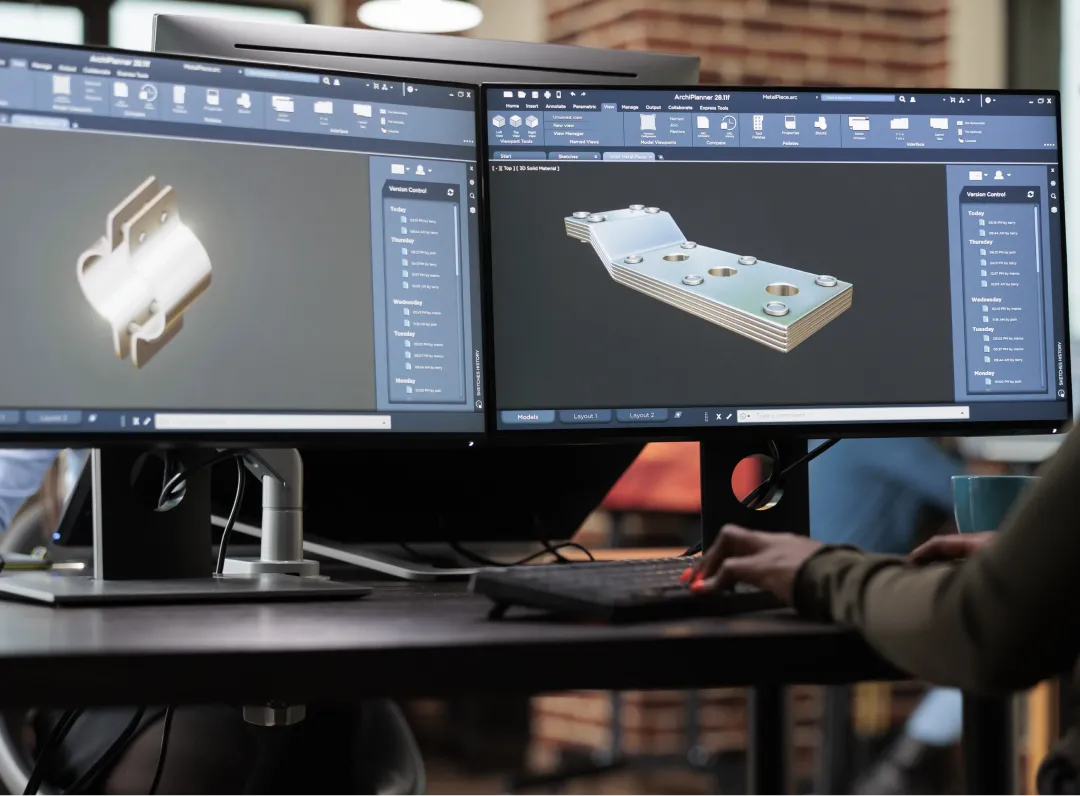

The first step is to design the part or product using a CAD

(Computer-Aided Design) software, which creates a digital model of the

part or product. The CAD software allows you to create and modify the

shape, size, and features of the part or product, as well as simulate

its functionality and performance.

Programming

The next step is to convert the CAD model into a set of instructions or

code that the CNC machine can understand and follow. This is done using

a CAM (Computer-Aided Manufacturing) software, which generates a G-code

or M-code file that contains the coordinates, speed, and direction of

the tool movement. The CAM software also optimizes the tool path and the

machining parameters, such as feed rate, spindle speed, and depth of

cut, to ensure the best results.

Setting up

The third step is to prepare the CNC machine and the workpiece for the

machining process. This involves selecting and installing the

appropriate machine tools, such as drills, mills, lathes, or grinders,

and securing the workpiece on the machine table or chuck. The machine

tools can have 3, 4, or 5 axes, which allow them to move in different

directions and angles. The machine tools are also equipped with sensors

and controllers that monitor and adjust the machining process.

Machining

The final step is to start the CNC machine and execute the program. The

CNC machine will follow the instructions and control the machine tools

to cut, shape, and form the workpiece according to the CAD model. The

CNC machine will also monitor the machining process and provide feedback

and adjustments if needed. The machining process can be fully automated

or semi-automated, depending on the complexity and requirements of the

part or product.

| CNC Turning |

CNC Milling |

CNC Drilling |

| 2-axis CNC lathes |

3-, 4- and 5-axis machines |

Upright, bench, radial drill presses |

Advantages of CNC Machining

CNC machining involves four main steps: Designing, Programming, Setting up, and

Machining. Here is a brief overview of each step:

Accuracy

CNC machining can produce parts and products with high precision and

accuracy, which can meet the strict specifications and tolerances

required by various industries and applications. CNC machining can also

ensure the repeatability and consistency of the parts and products,

which can reduce errors and waste.

Speed

CNC machining can reduce the production time and cost by using automated

processes and efficient machines, which can perform multiple operations

in a single setup and run continuously without human intervention. CNC

machining can also increase the productivity and profitability of the

manufacturing process, as well as the customer satisfaction and loyalty.

Flexibility

CNC machining can handle different types of materials, such as metal,

plastic, wood, or composite, and create complex and customized parts and

products that are difficult or impossible to make with manual methods.

CNC machining can also adapt to the changing needs and demands of the

customers, as well as the market trends and innovations.

Quality

CNC machining can ensure the quality and reliability of the parts and

products by using advanced machines, tools, and materials, as well as

quality control and inspection methods. CNC machining can also improve

the performance and functionality of the parts and products, as well as

their appearance and aesthetics.

Technical Specification

| CNC Process |

Tolerance |

| Lathe |

± 0.005" | 0.13mm |

| Router |

± 0.005" | 0.13mm |

| Router (Cutting Gaskets) |

± 0.030" | 0.762mm |

| 3-Axis Milling |

± 0.005" | 0.13mm |

| 5-Axis Milling |

± 0.005" | 0.13mm |

| Engraving |

± 0.005" | 0.13mm |

| Surface Roughness (Finish) |

125RA |

How Vexma Technologies Can Help You with CNC Machining

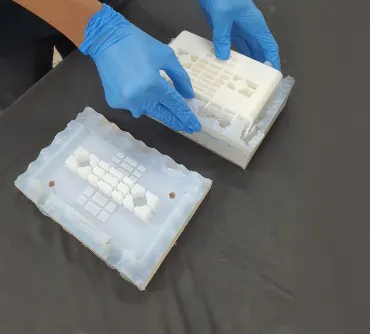

Vexma Technologies is a leading additive and advanced manufacturing service provider,

offering CNC machining solutions for various applications, such as prototyping, low-volume

production, tooling, and molding. Vexma Technologies has a team of experienced and skilled

engineers and machinists, who can handle any CNC machining project with precision and

efficiency. Vexma Technologies also offers other additive and advanced manufacturing

services, such as 3D printing, vacuum casting, design and analysis, new product development,

and reverse engineering.

Vexma Technologies is committed to delivering high-quality and cost-effective CNC machining

and manufacturing services to its customers, and to making CNC machining accessible and

affordable for everyone.

If you are interested in CNC machining and manufacturing services, you can contact Vexma

Technologies through Our website, email, or phone. You can also request a quote, a sample,

or a consultation from their team of experts. Vexma Technologies will help you turn your

ideas into reality, and to create value and impact with CNC machining.