Polymer Drone Parts: How 3D Printing Enables Lightweight & Strong UAV Designs

Unmanned Aerial Vehicles (UAVs) demand components that are lightweight, strong, and geometrically efficient. As drone applications expand across defense, logistics, surveying, agriculture, and industrial inspection, manufacturers are increasingly turning to polymer 3D printing to design and produce high-performance drone parts.

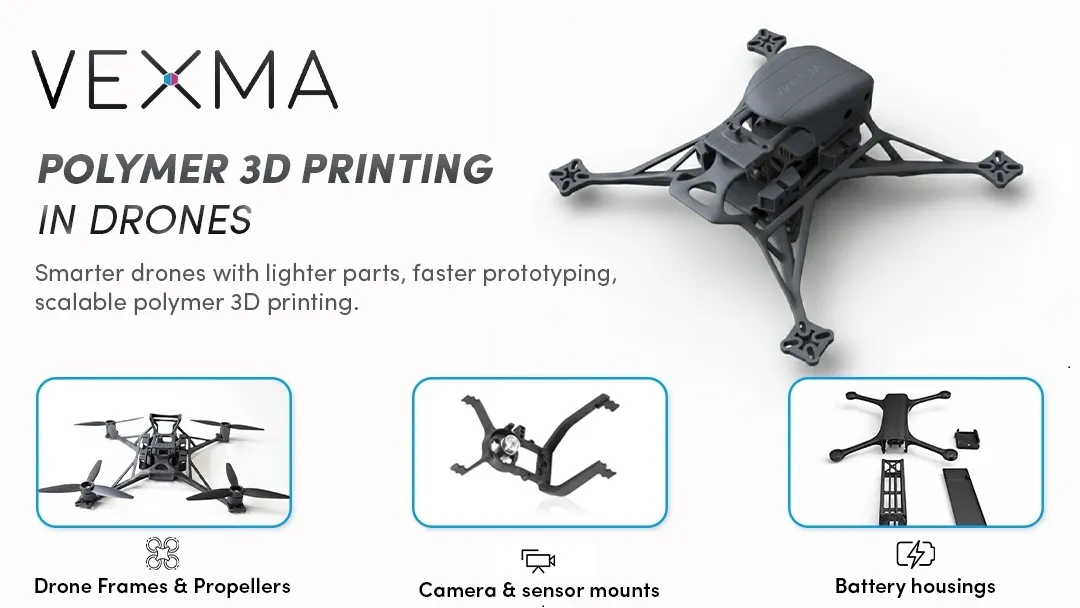

In this blog, we explore how polymer drone parts manufactured through advanced 3D printing technologies enable lighter structures, improved strength, faster development cycles, and cost-effective production, an approach adopted by Vexma to support next-generation UAV systems.

Why Polymer Drone Parts Matter in UAV Design

Weight is one of the most critical parameters in drone engineering. Every gram saved directly improves:

-> Flight time

-> Payload capacity

-> Maneuverability

-> Energy efficiency

Traditional manufacturing methods often impose design limitations, leading to overbuilt components. Polymer 3D printing eliminates these constraints, allowing engineers to create optimized drone parts without compromising structural performance.

How Polymer 3D Printing Transforms Drone Manufacturing

1. Lightweight Structures Without Strength Trade-Offs

Polymer 3D printing enables lattice structures, hollow geometries, and internal reinforcements that significantly reduce weight while maintaining strength. High-performance polymers such as PA12 and PA11 offer excellent strength-to-weight ratios, making them ideal for UAV frames, housings, and structural components.

2. Complex Drone Designs Made Manufacturable

Unlike CNC machining or injection moulding, 3D printing allows the production of complex, integrated drone parts in a single build. This design freedom results in:

-> Fewer assemblies

-> Reduced fasteners

-> Improved part reliability

Common Polymer Drone Parts Manufactured Using 3D Printing

Polymer 3D printing supports a wide range of functional drone components, including:

-> Lightweight drone frames

-> Motor mounts and brackets

-> Electronic enclosures and housings

-> Payload mounts and camera brackets

-> Landing gear and structural supports

-> Custom aerodynamic covers

These components are suitable for both rapid prototyping and end-use production.

PA12: An Ideal Polymer for Drone Applications

PA12 (Nylon 12) is one of the most widely used polymers in UAV manufacturing due to its:

-> High strength and stiffness

-> Excellent dimensional accuracy

-> Good impact resistance

-> Stability in outdoor and vibration-prone environments

PA12 performs reliably under demanding operating conditions, making it ideal for structural and functional drone parts. For many UAV applications, polymer drone parts strike the perfect balance between strength, weight, and cost.

Low-Batch & Production Manufacturing with 3D Printing

Polymer 3D printing excels in low-to-medium volume production, making it ideal for:

-> UAV startups

-> Pilot production runs

-> Customized drone variants

-> On-demand spare parts

Manufacturers can scale from 1 to 10,000 units without tooling investment, reducing risk and accelerating time to market. Vexma leverages this flexibility to support both prototype and production-ready UAV components.

Industries Using Polymer Drone Parts

Polymer 3D printing supports UAV applications across multiple industries, including:

-> Defense & surveillance

-> Logistics & delivery drones

-> Agriculture & mapping

-> Industrial inspection

Design Freedom Enables Better UAV Performance

Additive manufacturing enables Design for Additive Manufacturing (DfAM) principles such as:

-> Topology optimization

-> Integrated cable routing

-> Weight-balanced structures

-> Improved aerodynamics

The result is drones that are lighter, stronger, and more efficient.

Why Choose Polymer 3D Printing for UAV Manufacturing

-> Faster product development

-> Reduced part weight

-> No tooling or moulds

-> High repeatability

-> Production-ready quality

Polymer 3D printing is no longer limited to prototyping; it has become a core manufacturing technology for modern UAV systems.

Conclusion

Polymer drone parts manufactured through 3D printing are redefining how UAVs are designed and built. By enabling lightweight, strong, and highly optimized components, additive manufacturing helps drone manufacturers innovate faster, reduce costs, and achieve superior performance.

Vexma acts as a full UAV manufacturing partner, powered by dual technologies and a wide range of engineering, finishing, and production capabilities. This end-to-end approach enables drone brands to move seamlessly from idea to prototype to field-ready parts, faster, stronger, and more reliably than ever before.