Next-Gen IoT-Enabled 3D Printed Drones with HP MJF Technology

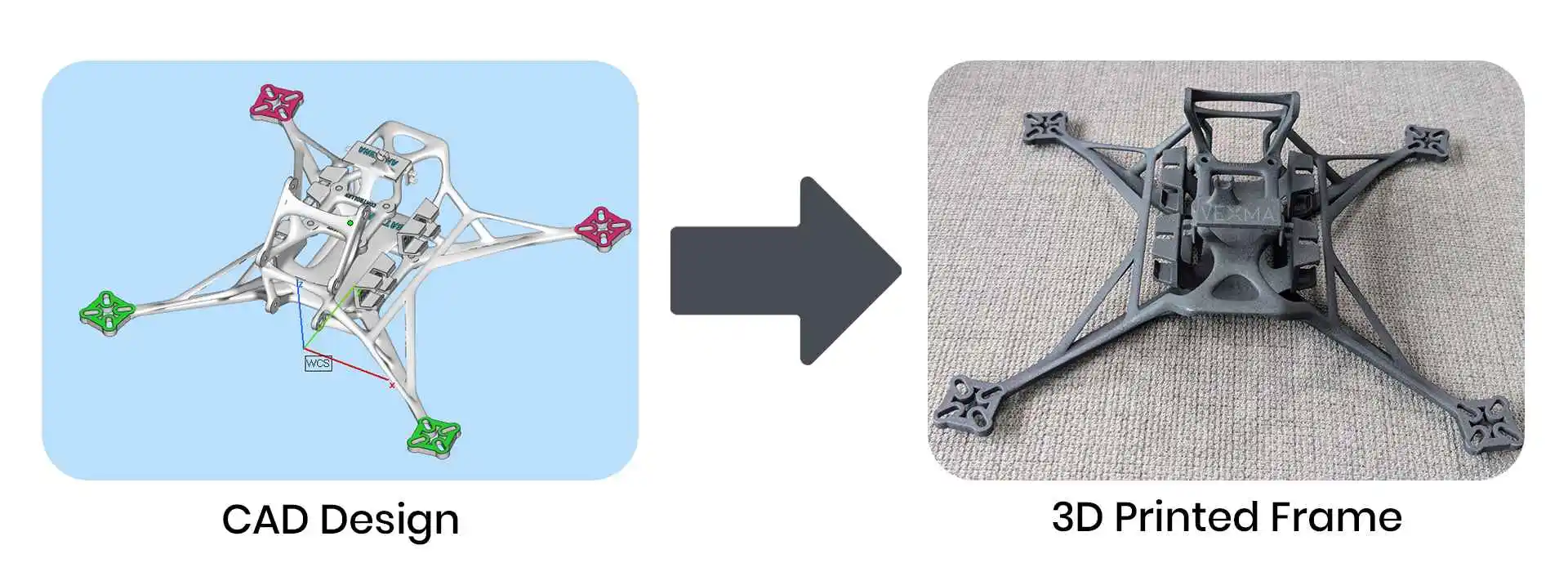

At Vexma Technologies, we specialize in Design for Additive Manufacturing (DfAM) to optimize drone frames using HP’s Multi Jet Fusion (MJF) technology - renowned for its isotropic properties and exceptional dimensional accuracy. Now, with the integration of IoT capabilities, our drones are not just mechanically advanced—they’re digitally intelligent.

As industries shift toward smarter, more connected systems, IoT and drone technology are converging to redefine how aerial platforms are designed, prototyped, and deployed. From real-time data collection to autonomous flight, our 3D printed drone components are engineered for both recreational and industrial IoT applications.

Why MJF Technology is a Game Changer for Drone Manufacturing

HP MJF technology is renowned for its superior accuracy, speed, and versatility. It enables us to create complex and intricate drone parts with exceptional strength and lightweight properties - something that traditional manufacturing methods simply can’t achieve. At Vexma Technologies, we utilize this advanced technology to produce drones that are not only high-performing but also resilient enough to withstand demanding environments.

What We Offer

-> IoT-Enabled Drone Solutions

-> Autonomous aerial surveillance

-> Real-time environmental monitoring

-> Smart agriculture and crop analytics

-> Infrastructure inspection and asset tracking

Key Advantages of 3D Printed Drones with HP MJF Technology:

Accelerated Prototyping: Time is money in the fast-paced world of drone development. With HP MJF, we drastically reduce the lead time for creating prototypes, allowing for faster iterations and quicker go-to-market solutions.

Custom Components: Every drone project has unique requirements, and our 3D printing capabilities enable the creation of fully customized parts tailored to specific needs, ensuring optimal functionality and design freedom.

Lightweight Excellence: The lightweight nature of our 3D printed parts significantly enhances the drones performance. Lighter drones are more agile, fuel-efficient, and have longer flight times, making them ideal for both commercial and recreational use.

Complex Geometries: With HP MJF, we're able to produce geometrically complex parts that are difficult or impossible to manufacture through traditional methods. This opens up new possibilities in drone design, where precision and complexity are key.

Efficient Production: Whether it's a one-off prototype or large-scale production, HP MJF ensures consistent quality and cost-effective production. The efficiency of this technology makes it ideal for both short-run and high-volume manufacturing.

The MJF Drone Body met industry standards for strength, lightweight efficiency, and design versatility, making it ideal for high-performance drones. Explore the limitless possibilities with our 3D printed drones and take your innovation to new heights!

📢 Share Your Insights: Drone Industry Survey

We’re exploring how 3D printing and IoT integration are transforming the drone industry—from faster prototyping to smarter, connected aerial systems. If you're involved in drone development, we'd love to hear from you.

🕒 It only takes 3–4 minutes, and your responses will remain confidential.

👉 Take the Survey Now:

https://docs.google.com/forms/d/1W2Cl6OzR7qz3yMEeCQWmlER1hGAi-EcX4_BgmXgjbpU/viewform?edit_requested=true