How 3D Printing is Powering the Next Era of UAV Innovation

The drone and UAV industry is evolving at incredible speed - demanding lighter structures, smarter designs, rapid iteration, and reliable end-use production. Traditional manufacturing struggles to keep up with the pace of innovation, especially when drone designs must be continuously optimized for aerodynamics, payload efficiency, and performance.

This is where modern 3D printing technologies especially HP Multi Jet Fusion (MJF) and Metal Additive Manufacturing (Metal AM) have become the backbone of next-generation drone development. From prototyping to final production, 3D printing is enabling drone manufacturers to experiment faster, reduce weight, strengthen parts, and bring new UAV models to market in record time.

By combining the power of Metal Additive Manufacturing and HP Multi Jet Fusion, Vexma Technologies delivers a complete UAV manufacturing ecosystem - from lightweight functional polymer parts to robust, flight-ready metal components.

1. Why 3D Printing Fits the Drone Industry Perfectly

A drone is essentially a compact flying robot packed with engineering challenges:

-> It must be lightweight yet structurally stiff

-> It requires aerodynamic shapes and complex geometries

-> It needs rapid design revisions during development

-> It depends on durable housings, frames, and mounts

-> It often demands low-batch production or customization

3D printing solves all these challenges by offering freedom to design, freedom to iterate, and freedom to manufacture without tooling.

2. HP MJF: The Gold Standard for High-Strength Drone Components

HP MJF has become the go-to technology for drone OEMs due to its unmatched combination of:

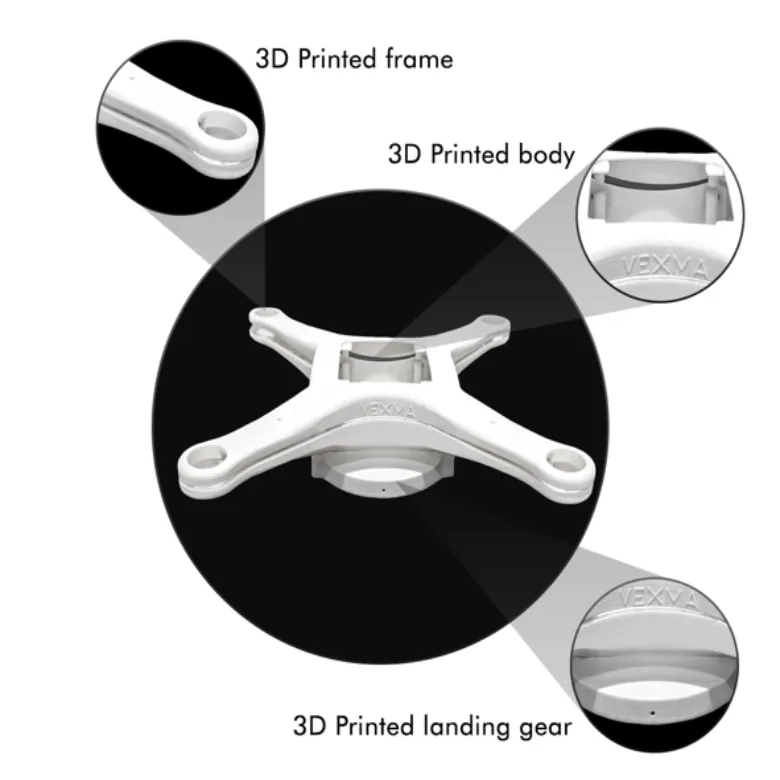

✔ Lightweight & High Tensile Strength - Perfect for frames, prop guards, payload housings, landing gear, and functional brackets.

✔ Precision for Sensor & Electronics Mounts - Camera mounts, gimbal components, and GPS enclosures can be printed with tight tolerances.

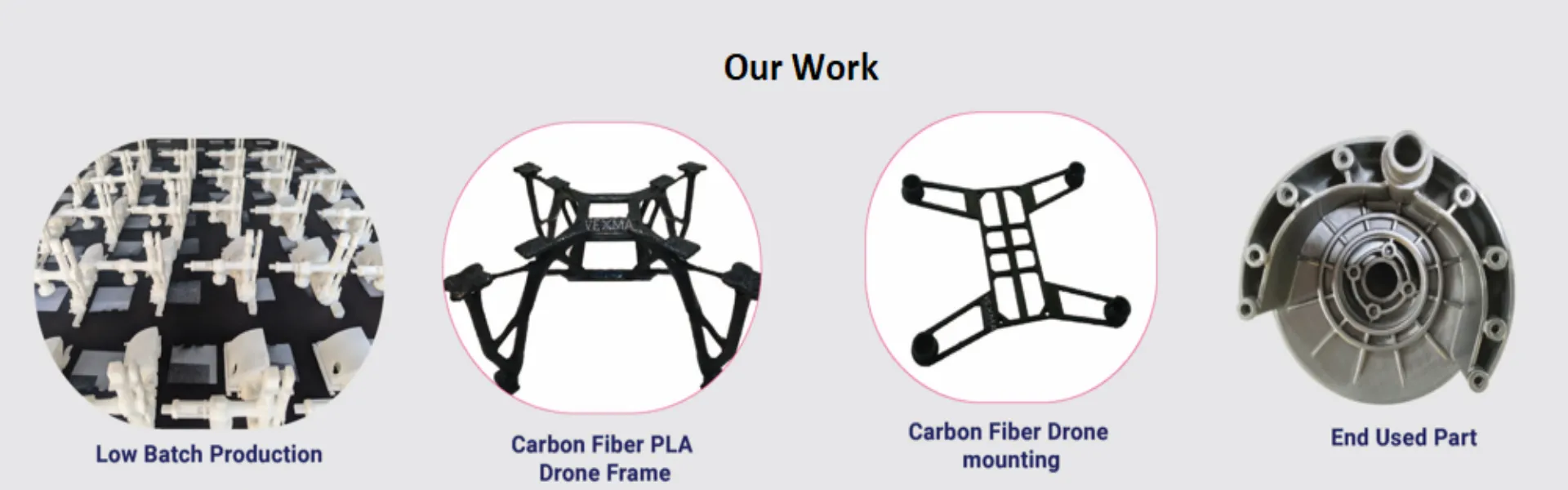

✔ Full Low-Batch Production - The ability to print 20–100+ identical drone components in a single build makes MJF ideal for startup drone companies and pilot projects.

✔ Carbon-Reinforced Structural Parts - Frames like the carbon-fibre PLA drone models you provided demonstrate how complex, stiff, lightweight structures can be produced quickly.

3. Metal AM: Strength, Stability & Performance for Critical UAV Hardware

Not all drone parts can be polymer-based, especially components that bear high load, heat, or vibration. This is where Metal Additive Manufacturing becomes essential.

Applications of Metal AM in Drones

-> Motor housings

-> Heat-resistant structural components

-> Connector brackets

-> High-stress frame components

-> Precision end-use casings

Why Metal AM Works So Well

-> High density and superior mechanical strength

-> Near-net geometry reduces machining

-> Connector brackets

-> Fast production vs casting or CNC

-> Supports aerospace-grade stainless steel and aluminium

Your shared end-use metal part image is a perfect real-world example of what modern drones require.

4. Vacuum Casting for Drone Prototypes & Pilot Batch Runs

Vacuum casting helps drone manufacturers bridge the gap between early prototyping and short-run production. It offers:

-> Smooth, injection-mold-like surface finish

-> Engineering-grade polymer properties

-> Connector brackets

-> Cost-effective low-volume batches

-> Fast turnaround

Common Drone Parts Made via Vacuum Casting

-> Drone frames

-> Propellers

-> Camera & sensor mounts

-> Landing gear

-> Battery casings

-> Prop guards

-> Antenna mounts

5. Real Drone Case Studies

Case Study 1: Carbon Fiber PLA Drone Frame

A custom-designed lightweight quadcopter frame manufactured using high-strength polymer and carbon reinforcement.

-> Increased stiffness

-> Reduced weight

-> Better thermal stability

-> Ready for field testing in under 48 hours

Case Study 2: Low-Batch Production of Prototyping Parts

Ideal for startups and OEMs testing multiple drone revisions simultaneously.

-> 30+ identical parts produced in a single cycle

-> Reduced weight

-> Reliable production for pre-commercial trials

Case Study 3: End-Use Metal Drone Component

Using Metal AM, Vexma Technologies delivered a complex, precision-engineered motor mount casing.

-> Near-net shape

-> High durability

-> Reduced cost vs conventional machining for small batches

-> Chrome-plated surface finish for enhanced corrosion resistance

Case Study 4: Carbon Fiber Drone Mounting Bracket

A lightweight, rigid, and vibration-resistant drone mounting bracket manufactured using carbon-fiber-reinforced polymer on our HP MJF ecosystem. Engineered for strength-to-weight performance and long-term durability.

-> High rigidity for stable motor & electronics mounting

-> Excellent vibration damping for smoother flight behavior

-> Reduced overall drone weight for longer flight time

-> Manufactured with precise tolerances for plug-and-play assembly

The MJF Drone Body met industry standards for strength, lightweight efficiency, and design versatility, making it ideal for high-performance drones. Explore the limitless possibilities with our 3D printed drones and take your innovation to new heights!

6. The New Age Era of Drone Manufacturing

Modern drones require faster innovation cycles, and 3D printing delivers exactly that:

✔ Rapid upgrades without tooling

✔ Quick replacement of malfunctioning components

✔ Better performance through structural optimization

✔ Full customization

Conclusion

With complete in-house prototyping-to-production support, Vexma acts as a full UAV manufacturing partner powered by dual technologies and a wide range of engineering, finishing, and manufacturing capabilities. This enables drone brands to move from idea → prototype → field-ready parts faster, stronger, and more reliably than ever. The future of drone and UAV manufacturing lies in digital, on-demand, high-performance production. With technologies like HP MJF and Metal AM, manufacturers can push boundaries, creating lighter, stronger, smarter drones without slowing down innovation.