India’s Next Industrial Revolution is 3D Printing

In today’s fast-paced manufacturing environment, industries across the globe are redefining how they design, prototype, and produce. One technology at the forefront of this transformation is Additive Manufacturing (AM) - commonly known as 3D printing. At Vexma Technologies, we believe this revolution is not a distant vision, but a present-day reality already shaping the future of India's industrial landscape.

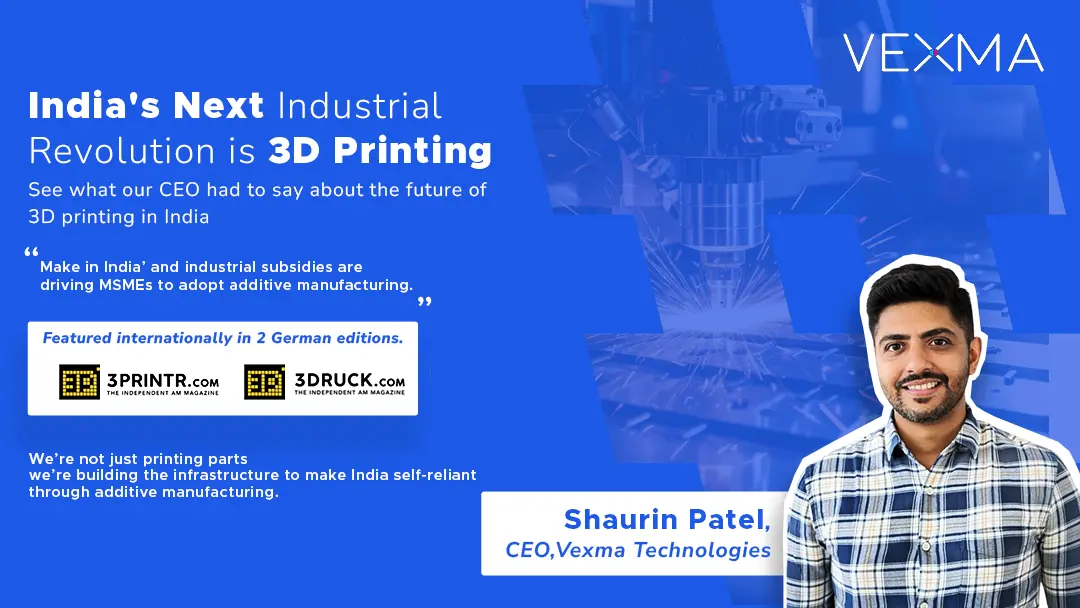

In an exclusive feature interview with 3Printr, Germany’s premier additive manufacturing publication, our CEO Shaurin Patel laid out Vexma’s forward-thinking vision for AM in India. This blog explores the insights from that interview and delves deeper into why Vexma sees AM not just as a buzzword - but as a foundational infrastructure for a new industrial era.

Additive Manufacturing: From Innovation to Industrial Backbone

Traditionally, manufacturing has relied on subtractive methods - milling, cutting, molding which involve material waste, tooling costs, and limited design freedom. In contrast, additive manufacturing builds parts layer by layer, allowing for unprecedented complexity, customization, and agility.

But at Vexma, we don’t view 3D printing as an alternative to traditional manufacturing, we see it as the backbone of a digital, decentralized, and demand-driven industrial future.

Why Additive Manufacturing Matters Now More Than Ever:

-> Faster Time to Market: Products can move from concept to prototype in days instead of months.

-> Cost-Efficiency at Low Volume: Ideal for rapid prototyping, short production runs, and custom applications.

-> Design Freedom: Engineers are no longer limited by the constraints of molds and machining tools.

-> Localized Production: Manufacturing closer to the end user reduces shipping, storage, and carbon impact.

-> Sustainable Manufacturing: Additive processes are inherently less wasteful than traditional ones.

India’s Moment: Why the Time Is Right for AM

India’s manufacturing sector is undergoing a major transformation. With Make in India initiatives, a growing startup ecosystem, and increasing investments in industrial automation, the country is on the cusp of becoming a global manufacturing powerhouse. But traditional methods alone won’t get us there. For India to compete globally, it needs:

-> Speed and flexibility in product development

-> Affordable access to cutting-edge technologies

-> Localized, on-demand production capabilities

-> Digital-first infrastructure to enable scalable innovation

This is where additive manufacturing fits in and where Vexma is leading the charge.

Vexma’s Role: Building the Digital Fabric of Indian Manufacturing

As one of India’s leading players in industrial 3D printing and product development, Vexma Technologies offers an end-to-end digital manufacturing platform. From ideation to final product, we integrate every step with advanced technology, deep engineering expertise, and a commitment to quality.

Our Capabilities Include:

-> Product Design & Engineering Services

-> DFAM (Design for Additive Manufacturing)

-> 3D Scanning & Reverse Engineering

-> High-Precision 3D Printing (FDM, SLA, SLS, MJF, etc.)

-> Post-Processing & Functional Testing

-> IoT-Integrated Prototyping

By offering a full-stack solution, we empower startups, MSMEs, and large enterprises to cut costs, speed up development, and bring better products to market faster.

Highlights from our CEO - Shaurin Patel’s Interview with 3Printr

In the 3Printr interview, Shaurin Patel emphasized how Vexma is not just adopting AM - we’re embedding it into the core of industrial operations.

Key Takeaways:

-> India’s readiness: The talent, demand, and industrial maturity are in place — what’s needed is access and infrastructure, which Vexma provides.

-> Localized ecosystems: Vexma enables just-in-time, on-demand production without the need for expensive tooling or long supply chains.

-> Beyond prototyping: Additive is no longer limited to concept validation — it’s now part of full-scale product development and even end-use manufacturing.

-> Sustainability goals: AM plays a key role in reducing material waste and enabling circular product life cycles.

Read the full interview with 3Printr here: https://www.3printr.com/driving-3d-printing-adoption-in-india-interview-with-vexma-technologies-ceo-shaurin-patel-3580743/

Looking ahead over the next 5 to 10 years, how do we envision the future of additive manufacturing in India and globally?

Over the next five to ten years, additive manufacturing is expected to become mainstream in the production of spare parts, tooling, and lightweight components. We foresee the rise of localized, distributed micro-factories playing a crucial role in enhancing supply chain resilience. Emerging sectors - such as bioprinting, 3D-printed electronics, and large-scale construction using additive manufacturing will further broaden industrial applications. Additionally, we anticipate increased use of smart materials, including self-healing, conductive, and recyclable polymers. With continued improvements in material consistency and automation, additive manufacturing will be at the core of digital, on-demand supply chains, both in India and globally.

Conclusion: A Future Built Layer by Layer

The future of manufacturing isn’t coming - it’s already here, and it’s being built layer by layer through additive technologies. At Vexma Technologies, we are proud to be pioneers of this shift in India, partnering with innovators to design smarter, build faster, and scale better.