Why Conformal Cooling is the Game-Changer for Injection Molding Companies

In the world of injection molding, reducing cycle time while maintaining part quality is the key to achieving cost-effective production. One of the most revolutionary advancements that has transformed plastic injection molding is the use of conformal cooling - a design and manufacturing approach made possible through 3D printing.

Understanding Conformal Cooling

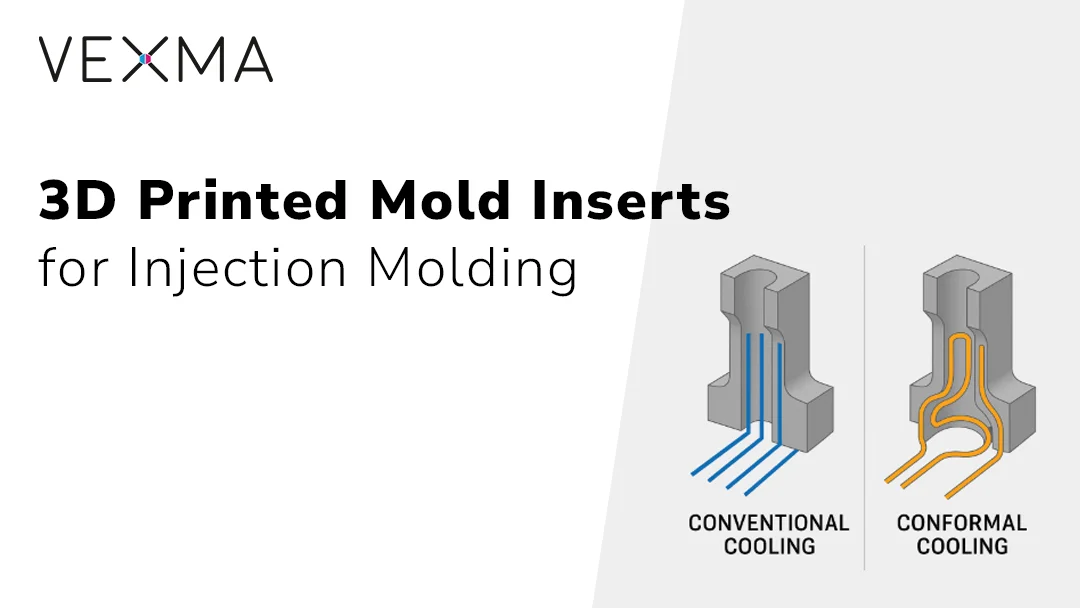

In traditional injection molding processing, cooling channels inside the mold are usually straight, created using conventional drilling methods. This limits their ability to follow the complex geometry of the part, leading to uneven cooling, higher injection molding cooling time, and potential defects like warping or sink marks.

Conformal cooling channels change that. By designing cooling channels in injection moulding to follow the contour of the part, heat is removed more evenly and efficiently. This drastically improves cooling time in injection molding, leading to faster cycle times and higher part quality.

Why 3D Printing is Essential for Conformal Cooling

Conventional machining cannot easily produce the complex shapes required for conformal cooling channels in injection moulding.

This is where conformal cooling 3D printing comes in. With advanced metal additive manufacturing, mold inserts with

intricate cooling channel injection molding designs can be produced with unmatched precision.

Metal 3D printing enables the creation of cooling pathways that twist and turn around part features, optimizing heat transfer. For injection molding companies and plastic die mould manufacturers, this technology offers a competitive advantage that traditional manufacturing methods simply cannot match.

Benefits of Conformal Cooling in Injection Molding

• Reduced Cooling Time:

With conformal cooling injection molding, the injection molding cooling time can be reduced by up to 40–60%, directly increasing productivity.

• Improved Part Quality:

Even temperature distribution reduces warping, shrinkage, and other defects common in plastic injection molding.

• Lower Operational Costs:

Shorter cycles mean higher throughput with the same equipment, reducing operational costs for injection moulding manufacturers and custom plastic injection moulding service providers.

• Design Freedom:

By using 3D printing for injection molding mold inserts, engineers can achieve cooling layouts previously impossible for injection molding die manufacturers.Applications Across Industries

Plastic injection molding companies, metal injection molding operations, and custom plastic injection moulding businesses are leveraging conformal cooling for a range of industries:

• Automotive:

Faster production of complex components

• Consumer goods:

Improved surface finish and dimensional accuracy.

• Medical:

Enhanced precision for complex plastic components.

• Packaging:

Shorter production cycles for high-volume parts.Partnering with the Right Manufacturer

At Vexma Technologies, we specialize in conformal cooling 3D printing for plastic injection molding companies, metal injection molding, and custom plastic injection molding. By combining deep expertise in mold design with cutting-edge additive manufacturing, we help clients reduce cooling time in injection molding and improve overall production efficiency.

Conclusion

Conformal cooling represents one of the most impactful innovations in injection molding processing. Enabled by 3D printing, it allows plastic die mould manufacturers and injection molding companies to achieve faster cycles, better quality, and lower costs. As competition intensifies, adopting conformal cooling injection molding will be key for staying ahead in the global manufacturing market.

If you are looking to integrate conformal cooling channels into your molds, connect with our team to explore how Vexma’s 3D printing technology can transform your production efficiency.

Get a Free Quote

Ready to manufacture high-performance components with precision and speed?

With Vexma Technologies’ instant quote platform, you can upload your design file, configure

your specs, and get a geometry-based manufacturing quote in seconds — plus a free expert

consultation to optimize your part.

Start now at 👉 Get instant quote