Since our last Blog many enthusiastic technocrats came to us who had amazing

brain

storming ideas on using 3d printed solutions in their projects. One of them was

Mr.Shailesh Mali whosemain aim of his study was to determine the dimensional

accuracy, flatness, and surface texture obtained in FDM rapid prototype with ABS

(Acrylonitrile Butadiene Styrene) material.

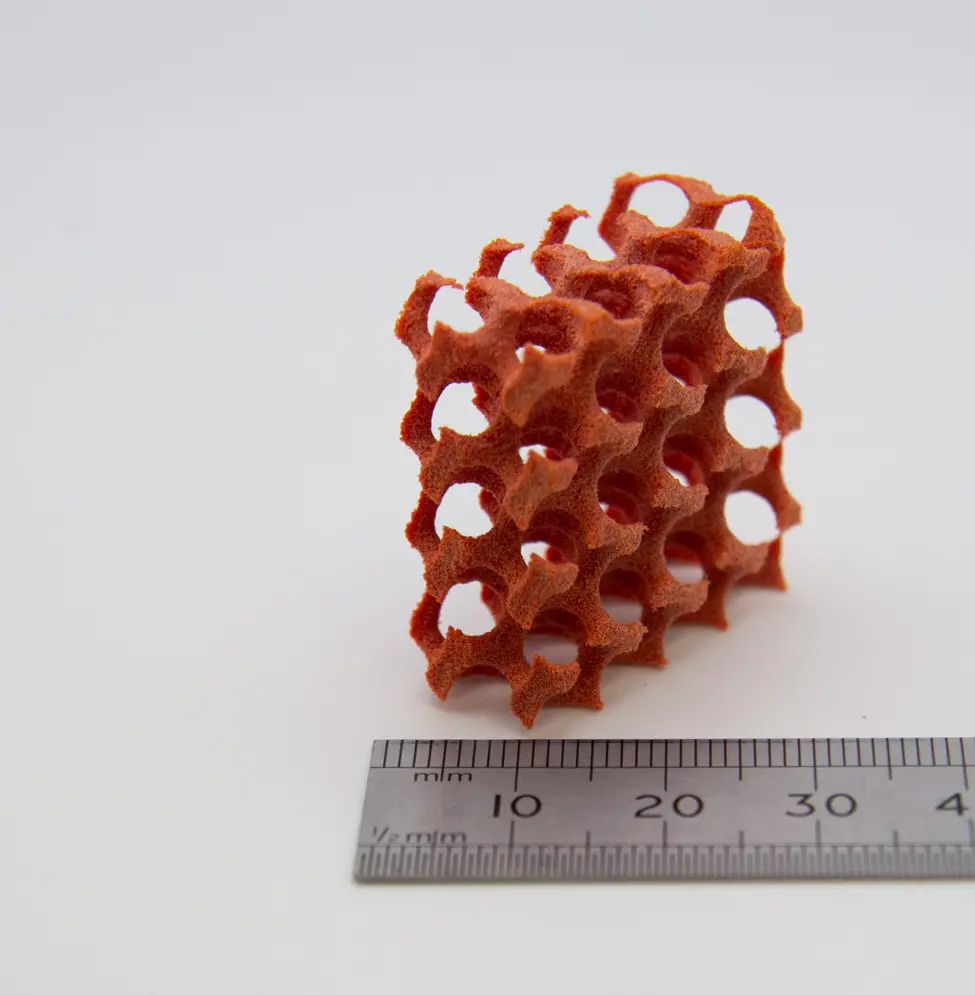

Main three parameter (layer thickness, orientation, and infill pattern) were

changed

in fused deposition modeling and different parameter like tensile strength,

compressive strength, impact strength etc was analyzed.

The goal of this prototype was to improve the energy efficiency and reduce the

power

consumption of a 3D printer by employing an innovative and validated heating

circuitry or platform without compromising print quality.

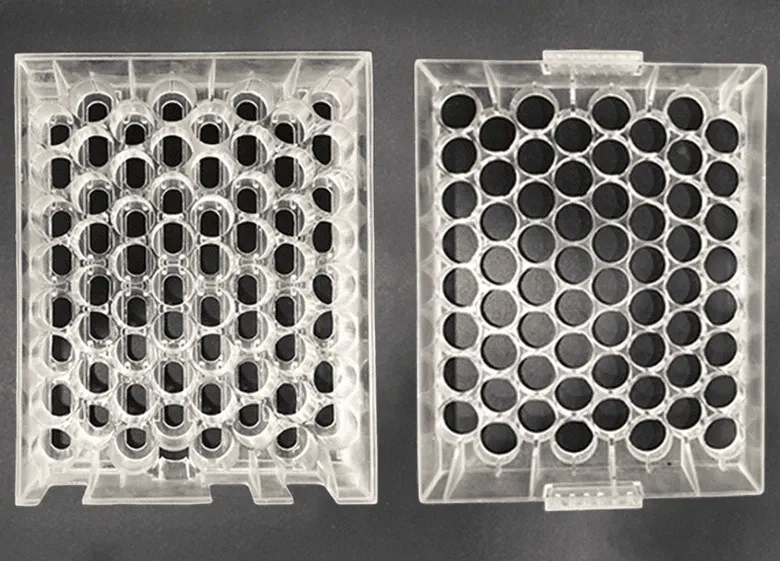

Tensile test specimens having dimensions 60 mm x 20 mm x 5 mm tests have been

conducted by changing the infill patterns like linier, hexagonal and diamond for

measuring Tensile strength (ASTMD 638). Parts are modeled and experiment is

conducted as per ISO R527:1966 for tensile test.