How 3D Printed Scale Models Are Game Changers for Industrial Innovation

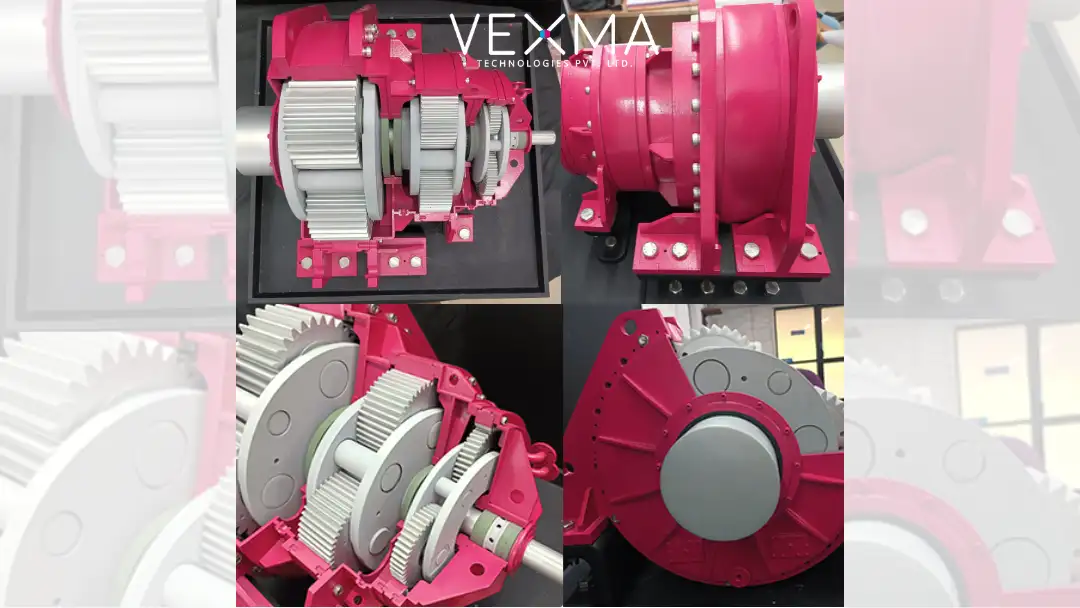

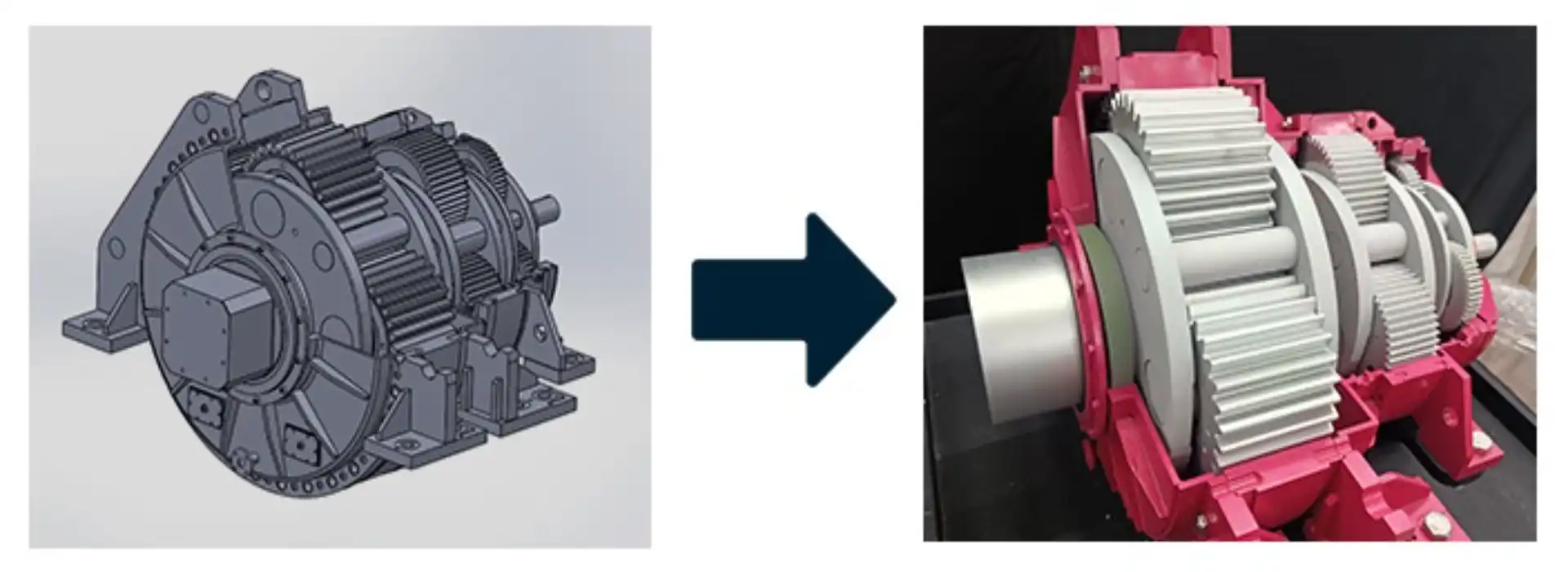

In the realm of precision engineering, 3D printed scale models have emerged as transformative tools, enabling industries to bridge the gap between conceptual designs and functional applications. One such innovation is Vexma Technologies' Foot-Mounted Planetary Gearbox Scale Model - a precision engineered masterpiece that exemplifies the power of 3D printing in modern manufacturing.

This scale model is a detailed representation of the efficient and compact planetary gearbox, widely used for high torque transfer in industries such as automotive, aerospace, and manufacturing. The design, created with PA12 nylon using advanced HP Multi Jet Fusion (HP MJF) technology, highlights the true potential of 3D printing for achieving intricate details and robust functionality.

Key Features

Size: 500mm (L) x 475mm (B) x 367mm (H)

High Torque Transfer: Accurately demonstrates the gearbox's ability to distribute torque efficiently.

Foot Mounting: Ensures stability and alignment in real-world setups.

Versatile Applications: Showcases use cases across multiple industries, including aerospace, automotive, and heavy machinery.

Why 3D Printed Models Are Industry Game Changers

3D printing has revolutionized how industries approach prototyping, design validation, and demonstration. Here’s why scale models like the planetary gearbox are making waves:

1. Detailed Replication of Complex Mechanisms

The intricate design of the

planetary gearbox, including its moving parts,

is accurately replicated with 3D printing. This level of detail makes it easier to

demonstrate mechanical functions during exhibitions and client presentations.

2. Customization and Design Flexibility

From unique geometries to specific

scaling requirements,

3D printing allows complete customization. This flexibility enables manufacturers to

adapt scale models to specific industrial needs or audiences.

3. Cost-Effective and Time-Saving Prototyping

Traditional manufacturing

methods for prototypes are time-intensive and expensive.

3D printing significantly reduces both the cost and turnaround time, accelerating

innovation cycles.

4. Realistic Representation for Better Understanding

Whether it’s for client

presentations or engineering teams, 3D printed

scale models provide a tangible, realistic understanding of complex machinery.

5. Ease of Transportation and Showcasing

Lightweight materials like PA12

ensure that the models are easy to transport and

set up, making them perfect for exhibitions and demonstrations.

The Foot-Mounted Planetary Gearbox Scale Model is a testament to the capabilities of 3D printing in transforming industry practices. With precise engineering, superior materials, and cutting-edge technology, this model encapsulates the essence of innovation.

Industries no longer need to rely on theoretical explanations or digital renderings. Instead, they can now leverage 3D printed scale models to communicate ideas effectively, validate designs, and inspire confidence in their solutions.

At Vexma Technologies, we’re dedicated to pushing the boundaries of what's possible with 3D printing. The Foot-Mounted Planetary Gearbox Scale Model is just one example of how we empower industries to turn their ideas into reality. Want to learn more about how our 3D printing services can revolutionize your projects? Contact us today and bring precision engineering to life.