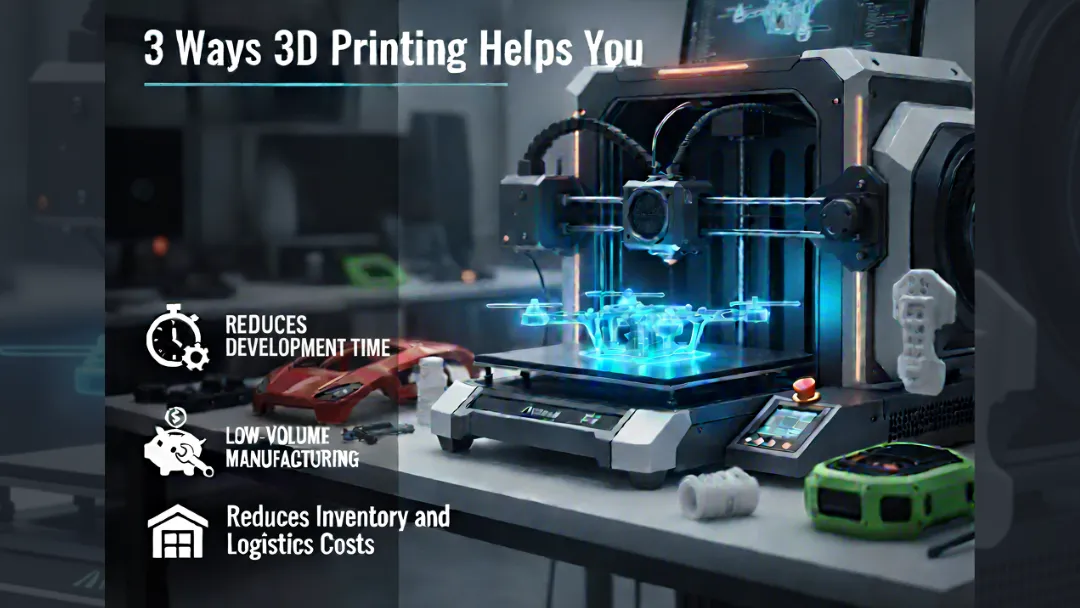

3 Proven Benefits of 3D Printing for Faster, Cost-Effective Production

In today's fast-paced and cost-sensitive industrial landscape, businesses are constantly looking for ways to optimize operations, reduce overheads, and bring products to market faster. One technology that has significantly transformed how products are designed, tested, and manufactured is 3D printing.

1. Rapid Prototyping Reduces Development Time

Traditional prototyping methods, such as CNC machining or injection moulding, can take days or even weeks to deliver a single iteration of a product. With 3D printing for prototyping, you can go from CAD model to physical prototype in a matter of hours.

How it saves time and money:

-> Quick turnaround: Create multiple design iterations in a day.

-> In-house prototyping: Reduces dependency on external vendors.

-> Lower material waste: Additive process only uses material where needed.

-> Faster decision-making: Get real-time feedback on design changes.

This is particularly valuable for product development teams that rely on rapid iteration and testing to refine a design before full-scale production.

2. Cost-Effective Low-Volume Manufacturing

For small to mid-sized production runs, traditional manufacturing often becomes uneconomical due to high tooling and setup costs. This is where 3D printing for manufacturing excels.

Key cost benefits:

-> No tooling required: Eliminates the expense and time associated with mold-making.

-> Custom parts at no extra cost: Producing one-off or highly customized parts costs nearly the same as mass-producing identical items.

-> Shorter supply chain: Manufacture on-demand, closer to where parts are needed.

Industries such as aerospace, automotive, medical devices, and consumer electronics are increasingly turning to 3D printing for producing end-use parts without the burden of high overhead.

3. Reduces Inventory and Logistics Costs

With traditional manufacturing, companies often overproduce to justify tooling costs and meet minimum order quantities. This leads to excess inventory, warehousing expenses, and the risk of obsolescence. 3D printing supports on-demand production, which means businesses only produce what they need, when they need it.

Strategic advantages:

-> Digital inventory: Store design files instead of physical stock.

-> On-demand production: Eliminate unnecessary storage costs.

-> Faster fulfillment: Manufacture parts closer to the point of use.

This approach aligns perfectly with lean manufacturing principles and helps reduce long-term operational costs.

Whether you’re a startup working on your first prototype or an established manufacturer looking to optimize your supply chain, 3D printing technology offers a smart, scalable solution to streamline processes and cut costs. From reducing production lead times to eliminating tooling costs, the benefits of additive manufacturing are both immediate and long-term.

At Vexma Technologies, we specialize in delivering end-to-end 3D printing solutions that empower businesses to innovate faster and more affordably. If you're looking to explore how 3D printing can save your time and money, connect with our experts today.