The ZR300 material exhibits excellent dimensional stability and retains its strength effectively even in environments with high humidity levels. It shares similarities with ABS in terms of surface quality, offering parts with a smooth finish, high elongation, and impressive flexibility. The liquid resin used in the printing process has a low viscosity and dries quickly upon exposure to light, allowing for easy application, effortless cleaning of both parts and machines, and the ability to recoat if necessary.

Furthermore, its superior green strength minimizes the need for extensive post-processing, resulting in efficient production. With its ABS-like pearl white color, the SLA resin enables the construction of accurate and durable parts, as the liquid resin starts off transparent and cures into a distinct pearl white appearance during the printing process.

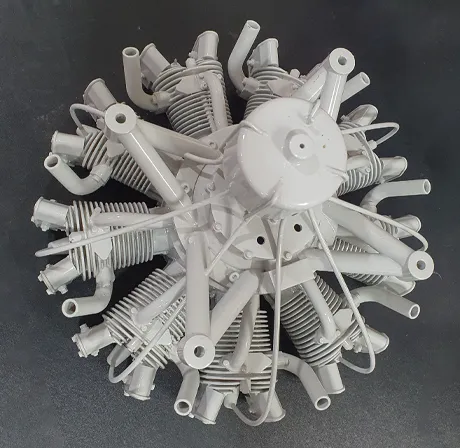

ZR300 is used in automotive applications such as engine components, fuel system parts, intake manifolds, and structural components. Its high strength, heat resistance, and durability make it suitable for demanding automotive environments.

ZR300 is utilized in the aerospace and aviation industry for manufacturing components like aircraft engine parts, turbine blades, and structural components. Its excellent heat resistance, high strength-to-weight ratio, and corrosion resistance are beneficial in these critical applications.

ZR300 is employed in the oil and gas sector for various applications including valves, pumps, fittings, and pipes. Its resistance to corrosion, high pressure, and extreme temperatures makes it suitable for harsh environments in oil and gas exploration, production, and processing.

ZR300 is used in chemical processing applications where resistance to corrosion from acids, alkalis, and other harsh chemicals is required. It is used in equipment such as reactors, heat exchangers, and storage tanks.

ZR300 is utilized in medical and healthcare applications due to its biocompatibility and resistance to body fluids. It is used for surgical instruments, dental implants, prosthetics, and medical devices.

ZR300 finds applications in the electronics and electrical industry for manufacturing connectors, terminals, and components that require high temperature resistance and electrical insulation properties.

ZR300 is used in marine applications such as shipbuilding and offshore structures. Its corrosion resistance, strength, and durability make it suitable for marine environments.

ZR300 is employed in various industrial equipment such as pumps, valves, gears, and bearings due to its high strength, wear resistance, and dimensional stability.

| Property | Value |

|---|---|

| Density | 1.13 g/cm3 @ 25 ℃ |

| Flexural modulus, Mpa | 1700-2200 |

| Flexural strength, Mpa | 64-81 |

| Tensile modulus, MPa | 1600-2200 |

| Tensile strength | 37-45Mpa |

| Elongation at break | 5 -8% |

| Heat deflection temperature, ℃ | 60 |

| Glass transition,Tg ,℃ | 68 |

| Coefficient of thermal expension, ℃ | 100*E-6 |