Driving the Future: How Vexma Technologies is Revolutionizing the Automotive Industry with 3D Printing

In today’s fast-paced and innovation-driven automotive sector, manufacturers face immense pressure to reduce production time, lower costs, and stay ahead of technological trends. At the heart of this transformation lies additive manufacturing - a disruptive technology that’s redefining how vehicles are designed, prototyped, and produced.

At Vexma Technologies, we are proud to be a catalyst for this change. As a trusted manufacturing partner in India, we deliver advanced rapid prototyping, low-volume production, and on-demand 3D printing solutions for the automotive ecosystem.

Whether it's prototyping functional parts or manufacturing production-grade components, our comprehensive service offering supports every stage of the product development lifecycle.

The Need for Speed: Why the Automotive Industry is Turning to 3D Printing

Traditionally, automotive manufacturing involves long lead times, expensive tooling, and minimal flexibility. Even a single design change can delay entire production cycles.

Additive manufacturing allows automotive companies to move from CAD design to physical part in a matter of days, enabling rapid iterations and quicker decision-making. This not only accelerates time-to-market but also empowers design teams to experiment with complex geometries that were previously impossible or cost-prohibitive to produce.

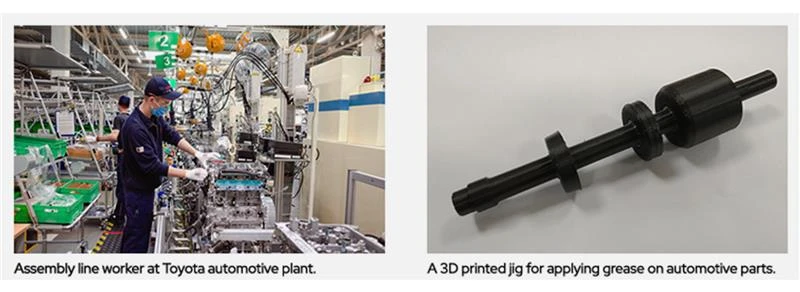

Companies like Toyota, Mahindra, Tata, Ford, General Motors and many more have already adopted 3D printing in their production lines to manufacture custom jigs, fixtures, and assembly tools. These in-house tools improve assembly precision, reduce human error, and enhance workflow efficiency - all while cutting costs and setup time significantly.

Real-World Applications: How 3D Printing is Powering Automotive Innovation

The impact of 3D printing extends far beyond just tooling. It’s being used across a variety of automotive functions, including aerodynamic testing, thermal analysis, ergonomic validation, and more.

For example:

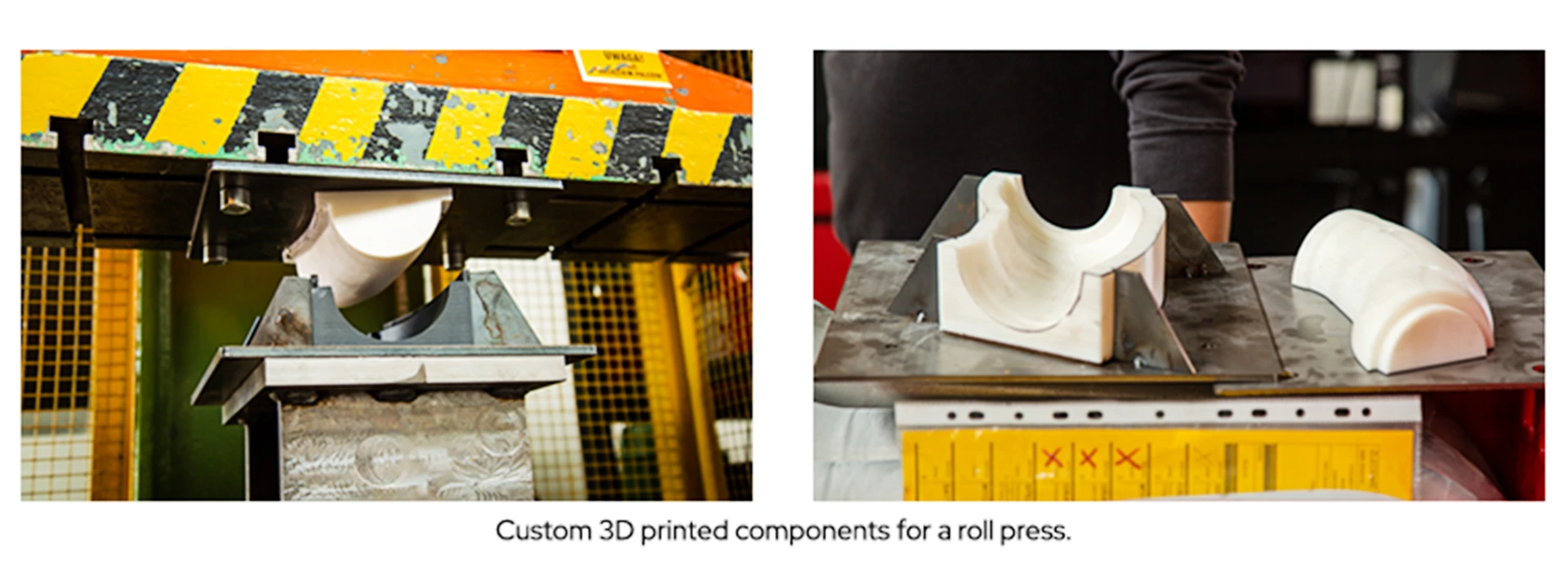

-> RM Motors, a Polish automotive parts manufacturer, integrated industrial 3D printers into their factory floor. They now 3D print custom components for their exhaust system machines, making their operations faster and more efficient.

-> Vins Motors, an Italian firm founded by former Ferrari engineers, used 3D printing to develop a revolutionary two-stroke engine for their performance motorbike, the Duecinquanta. The engine and aerodynamic parts were extensively prototyped using 3D printed models, allowing for high-speed development with real-world performance testing.

These examples highlight the role of additive manufacturing in high-performance automotive engineering - a space where Vexma Technologies continues to add value.

3D Printed Spare Parts: A Game Changer for Legacy Vehicles

One of the most exciting areas where 3D printing shines is in aftermarket and legacy vehicle parts. Classic cars and discontinued models often face a shortage of spare components. Traditional methods require expensive custom tooling and long waits - if replacement parts are even available.

With on-demand 3D printing, Vexma Tech enables:

• Reproduction of discontinued or rare parts

• Custom-fit components for vintage vehicles

• Functional prototypes that match OEM specifications

Our DMLS (Direct Metal Laser Sintering) technology is ideal for producing strong, heat-resistant metal parts, while SLA and SLS are perfect for fine-detail and functional plastic parts used in interior, dashboard, or under-the-hood components.

Vexma’s Manufacturing Capabilities

As a vertically integrated service provider, Vexma Technologies offers more than just printing. We are a one-stop solution for automotive design, prototyping, and production.

Our capabilities include:

• 3D Printing (FDM, SLA, SLS, DMLS)

• Vacuum Casting and CNC Machining

• Custom Tooling and Fixtures

• Low-Volume Batch Manufacturing

• Industrial Design and Product Development

Our facilities are equipped to support full product lifecycle development - from conceptual design to final production, with full quality assurance and material traceability.

Smarter, Faster, and Greener

In addition to performance, sustainability is now a key metric for the modern automotive manufacturer. 3D printing contributes to a leaner and more environmentally conscious production cycle by:

• Minimizing raw material waste through precise, layer-by-layer manufacturing

• Reducing carbon footprint via localized and on-demand production

• Eliminating the need for energy-intensive tooling and molds

This aligns perfectly with the global push for greener, more circular manufacturing models - and positions Vexma as a strategic partner in sustainable automotive innovation.

Why Choose Vexma for Automotive 3D Printing?

With years of expertise, cutting-edge technology, and a commitment to quality, Vexma Technologies delivers measurable value to OEMs, Tier 1 suppliers, and engineering design teams. Here's why companies trust us:

We offer:

• Fast lead times for urgent prototyping and testing

• End-to-end support from design optimization to delivery

• Proven success across use cases in tooling, functional parts, and consumer-ready products

Whether you're building EV components, lightweight structural parts, or custom brackets, we help you reduce cost, improve performance, and accelerate innovation.

Ready to Transform Your Automotive Manufacturing?

The future of automotive production is digital, agile, and additive and it’s happening now. Join global innovators who are already leveraging 3D printing in automotive applications to stay ahead of the curve.

👉 For details, visit our YouTube Channel:

https://www.youtube.com/@Vexmatech/videosGet a Free Quote

Ready to manufacture high-performance components with precision and speed?

With Vexma Technologies’ instant quote platform, you can upload your design file, configure

your specs, and get a geometry-based manufacturing quote in seconds — plus a free expert

consultation to optimize your part.

Start now at 👉 Get instant quote