How 3D Printing Improves Efficiency in Tyre & Mould Manufacturing

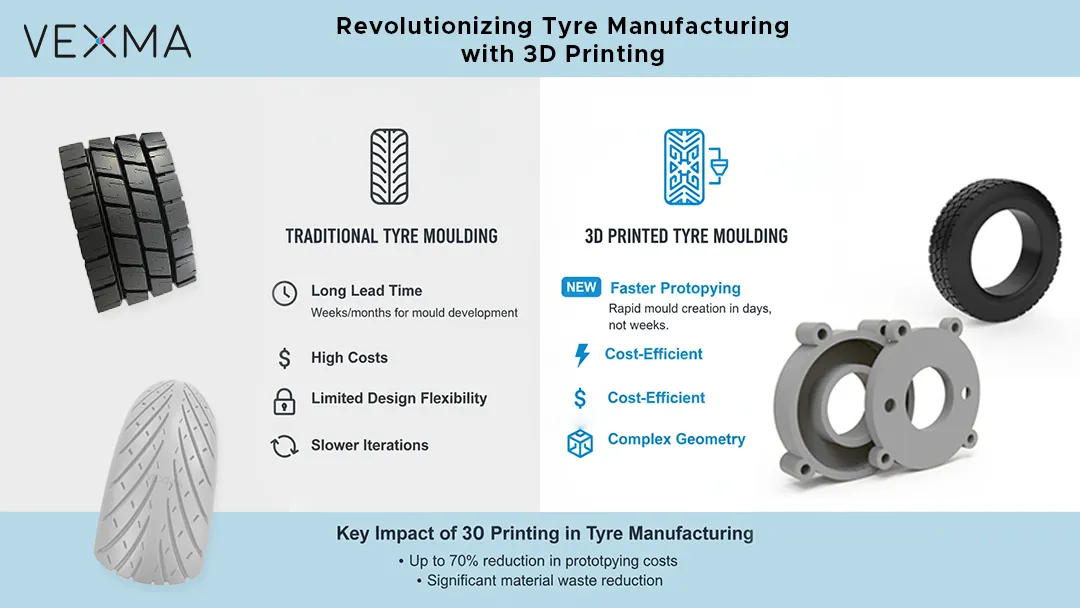

In the automotive industry, tyres are more than just components - they are critical to safety, performance, and efficiency. Behind every high-quality tyre lies a precisely engineered mould, which defines tread patterns, surface textures, and overall durability. Traditionally, manufacturing tyre moulds has been a complex, labour-intensive, and time-consuming process, often involving CNC machining, multiple tooling stages, and significant costs.

With the rise of additive manufacturing, or 3D printing, tyre mould development is undergoing a dramatic transformation. This technology is unlocking possibilities that were once impossible with conventional methods, enabling manufacturers to design, test, and scale moulds faster than ever before.

Why 3D Printing for Tyre Moulds?

-> Unmatched Design Flexibility: Complex tread geometries, sipes, grooves, and micro-patterns can be created directly with 3D printing. This eliminates design limitations and opens the door to innovative performance-driven tyre designs.

-> Rapid Prototyping & Iteration: What traditionally took weeks or months can now be achieved in days. Tyre manufacturers can prototype moulds quickly, test performance, and fine-tune designs with minimal delays.

-> Reduced Costs: By eliminating expensive tooling and machining steps, 3D printing lowers the cost per mould iteration, making experimentation and customisation far more affordable.

-> Lightweight Inserts & Components: 3D printed metal mould inserts can be produced with optimised internal structures, reducing overall weight while maintaining strength and durability.

-> Sustainability Advantage: Additive manufacturing uses material more efficiently, cutting down waste compared to subtractive processes and reducing the environmental footprint of mould production.

Industrial Impact

For tyre manufacturers, adopting 3D printing means:

-> Faster Product Development: Rapidly move from concept to production-ready tyres.

-> Better Performance Testing: Quickly test new tread designs and surface structures in real-world conditions.

-> Custom & Small-Batch Production: Cater to niche markets such as motorsports, aviation tyres, or specialised off-road tyres without high tooling costs.

-> Innovation at Scale: Leverage digital manufacturing to stay ahead in an increasingly competitive industry.

Case Study: Cutting Lead Times with 3D Printed Tyre Mould Inserts

A leading automotive supplier partnered with a 3D printing service provider to experiment with metal 3D printed tyre mould inserts. Traditionally, producing a steel mould insert through machining required 8–10 weeks and involved multiple suppliers.

By switching to additive manufacturing:

The same insert was produced in just 2 weeks, reducing development time by nearly 70%.

The printed mould featured integrated conformal cooling channels, which improved cooling efficiency during tyre curing by 30%, leading to faster cycle times.

The cost of reworking design iterations dropped significantly since digital files could be adjusted and reprinted without retooling.

This real-world example highlights how 3D printing enables faster prototyping, smarter mould design, and significant time-to-market advantages for tyre manufacturers.

The Road Ahead

The application of 3D printing in tyre mould manufacturing is still evolving, but its impact is undeniable. By combining design innovation, faster turnaround, and sustainable practices, additive manufacturing is reshaping how tyres are imagined, tested, and brought to market.

At Vexma Technologies, we empower tyre and mould manufacturers with cutting-edge 3D printing solutions, helping them stay ahead in a rapidly evolving industry. From prototyping to end-use parts, our expertise ensures your production is smarter, faster, and more efficient.

Get a Free Quote

Ready to manufacture high-performance components with precision and speed?

With Vexma Technologies’ instant quote platform, you can upload your design file, configure your specs, and get a geometry-based manufacturing quote in seconds — plus a free expert consultation to optimize your part.

Start now at 👉 Get instant quote