3D Printing in Metal

Transforms digital designs into precise metal parts with unparalleled speed and precision.

With the increasing demand for 3D printing, numerous companies have emerged offering 3D printing services in Chennai. Nevertheless, choosing the best one can prove to be quite challenging.

Are you searching for a company providing the best 3D Printing in Chennai? If yes, then Vexma Technologies is the best option for you.

When it comes to 3D printing in Chennai, our services offer unparalleled advantages that set us apart from the competition. At Vexma Technologies, we recognize that traditional prototyping methods, such as mould tools and injection tools, can be prohibitively expensive. Our innovative 3D printing solutions provide a cost-effective alternative, enabling you to create parts and tools without the hefty price tag. We are a design house offering tailored engineering design solutions, design for manufacturing, reverse engineering, and advanced additive manufacturing services, including both plastic and metal 3D printing.

One of the standout benefits of our 3D printing services is the ability to conduct affordable test prints. Before making a significant investment in your project, you can easily produce a prototype at a fraction of the cost. This technique minimizes financial risk and facilitates design iteration without advancing huge upfront costs.

In a fast-paced business scenario, speed is quite vital. Traditional prototyping takes days or sometimes even weeks for redesigns, to get it completed. In this kind of scenario, our team will be able to help you convert your concepts into a tangible model within hours. This gives an immense boost in speed for your project timelines and enables you to be more sensitive to feedback. Our advanced 3D printing technology empowers you to customize designs effortlessly. Whether you're looking to create unique shapes or intricate structures, our printers excel at handling complex geometries with ease. This flexibility allows you to personalize products according to your specific requirements, ensuring that the final output aligns perfectly with your vision.

Vexma specializes in drafting new shapes and structures. Our state-of-the-art 3D printers facilitate the creation of limitless designs, making it possible to outline complex figures that traditional manufacturing methods cannot achieve. This capability opens up new avenues for creativity and innovation in product development. Quality is paramount in our operations. We utilize high-grade materials and cutting-edge technology to ensure that every print meets stringent standards.

Amidst Chennai’s vibrant and ever-evolving creative community, our 3D printing services are built on a foundation of innovation, quality, and dedication. We offer more than just technology, we provide a pathway for your ideas to evolve into reality. Join us in turning your concepts into tangible, exceptional creations, and together, let’s craft a future that pushes boundaries and inspires limitless possibilities.

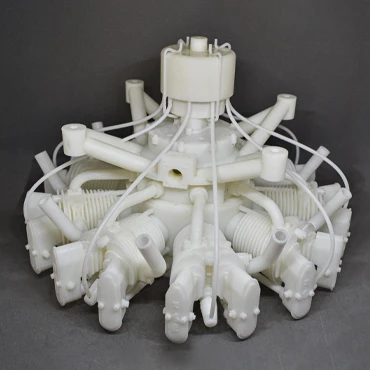

Transforms digital designs into precise metal parts with unparalleled speed and precision.

Utilizes SLA, MJF, FDM, and SLS technologies to create customized plastic designs with efficiency and versatility.

Producing high-quality components cost-effectively in small-batch production runs, offering diverse materials & finishes.

Optimizing product performance using FEA and CFD to assess structural integrity and fluid flow.

Integrating market research, CAD modeling, and Rapid Prototyping for a seamless journey from idea to market-ready solutions.

Replicating components using 3D scanning and modeling, facilitating product enhancements or replication.

Happy Clients

Project Complete

Years Of Experience

Parts Printed

Get More Technical Updates

With Our 10+ Years of Expertise, We are your trusted partners in turning your visions into tangible prototypes.

Get Every Single Updates

Talk to Sales

3D Printing, or Additive Manufacturing, has profoundly impacted numerous industries, revolutionizing traditional production methods.

In Aerospace, it enables the creation of lightweight and intricate components, enhancing fuel efficiency and performance without Compromising it’s strength.

The Healthcare and Medical sectors benefit from 3D printing's capability to produce custom implants, prosthetics, and even organs.

Automotive Manufacturers utilize it for rapid prototyping, customized parts, and the production of lightweight components, contributing to enhanced vehicle efficiency.

In Consumer Goods (FMCG), 3D printing allows for personalized designing and On-Demand low batch manufacturing resulting in companies to quickly iterate and test product designs, ensuring efficient development processes.

The Robotics Industry leverages its flexibility to produce complex and tailored components, fostering innovation.

Electrical Vehicle(EVs) manufacturers benefit from the lightweight and efficient designs achievable through 3D printing.

In the Defense Sector, it facilitates rapid prototyping, on-demand spare part production, and the creation of specialized components.

The Drone Industry utilizes 3D printing for lightweight structures and intricate designs, optimizing performance