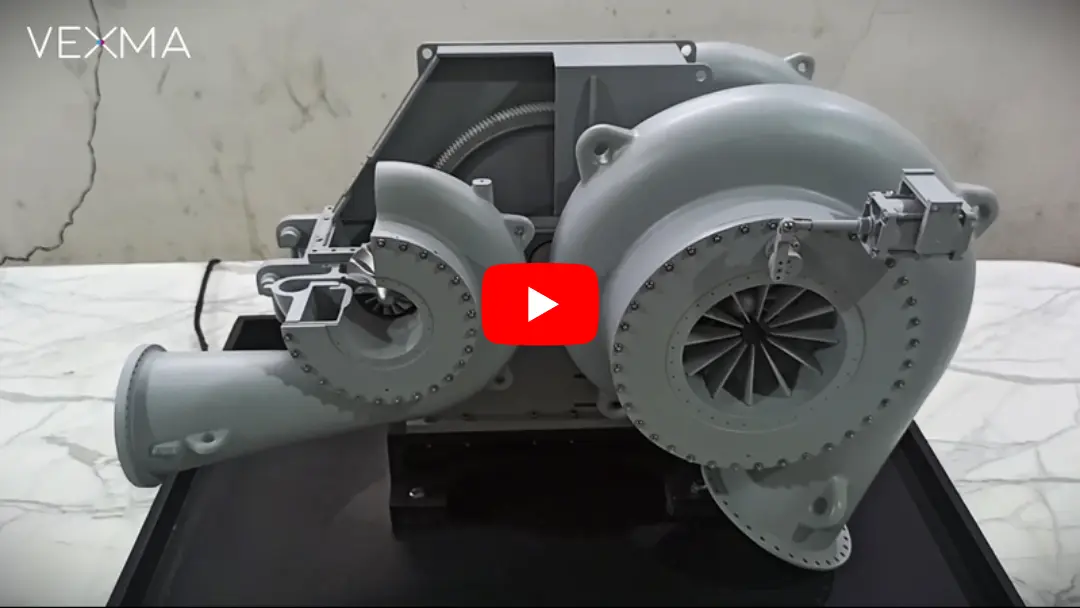

3D Printed Turbo Compressor Impeller – Industrial-Grade Scale Model for Exhibition

At Vexma Technologies, we bring engineering ideas to life with precision-crafted 3D printed scale models. Our latest project - Turbo Compressor Impeller - showcases the true capabilities of industrial 3D printing when applied to mechanical design, validation, and exhibition needs.

This scale model of a turbo compressor impeller is more than a replica. It is a functional representation that illustrates how advanced geometries and performance-critical features can be replicated through additive manufacturing.

Why Turbo Compressor Impellers?

Turbo compressors are essential components in industrial processes, used to increase the pressure and flow of gases in chemical plants, refineries, and HVAC systems. The impeller is the heart of this system, and its design directly impacts efficiency, performance, and reliability.

Creating a high-fidelity model allows manufacturers, engineers, and training institutions to:

• Explain operational principles

• Visualize complex internal structures

• Demonstrate design variations

• Improve communication during stakeholder presentations

The Role of 3D Printing in Scale Models

Additive manufacturing revolutionizes how we develop, present, and iterate on industrial components. This turbo compressor impeller was produced using industrial-grade 3D printing technology, enabling:

• Complex geometry reproduction:

Hollow cavities, curved blades, and radial symmetry are accurately replicated.• Material versatility:

Depending on requirements, materials can mimic the mechanical behavior or simply aesthetic quality.• Speed to production:

Rapid fabrication allows quicker turnaround compared to traditional prototyping.• Design validation:

Engineers can physically inspect the design before proceeding to functional testing or production tooling.Applications of the Scale Model

This 3D printed turbo compressor impeller model can be used across various industrial and educational contexts:

• Industrial Exhibitions:

Perfect for trade shows and expos, the model helps companies showcase their mechanical expertise in a tangible, engaging way.

• Mechanical Design Validation:

Before committing to expensive tooling or manufacturing, the scale model serves as a physical prototype for visual and structural assessment.

• Employee Training Programs:

New engineers and technicians can use the model to understand internal features and mechanical behavior in a hands-on environment.

• Client Demonstrations & Stakeholder Buy-In:

The model provides visual clarity for non-technical audiences, helping bridge the gap between concept and implementation.Packaging and Portability

At Vexma, packaging goes beyond protection—it's integral to the scale model experience, ensuring safe delivery across regions and countries.

Protection & Durability

Our packaging is built to safeguard intricate, fragile models from impacts, vibrations, and rough handling, maintaining structural integrity through repeated use.

Flight-Ready Cases

For global exhibitions and demos, we offer custom flight cases featuring:

• Tough, impact-resistant exteriors

• Foam-lined, model-specific interiors

• Lockable, wheeled designs with handles

• Weather-sealed for dust and moisture resistance

Sustainable & Reusable

We prioritize eco-conscious packaging:

• Reusable for long-term use

• Made from recyclable materials

• Designed to minimize single-use waste

Long-Term Utility

Even post-delivery, our packaging ensures:

• Safe storage between uses

• Protection during repeated transport

• Resistance to humidity and dust

👉 Watch the Turbo Compressor Impeller video on YouTube to see the exceptional level of detail and finishing we provide.