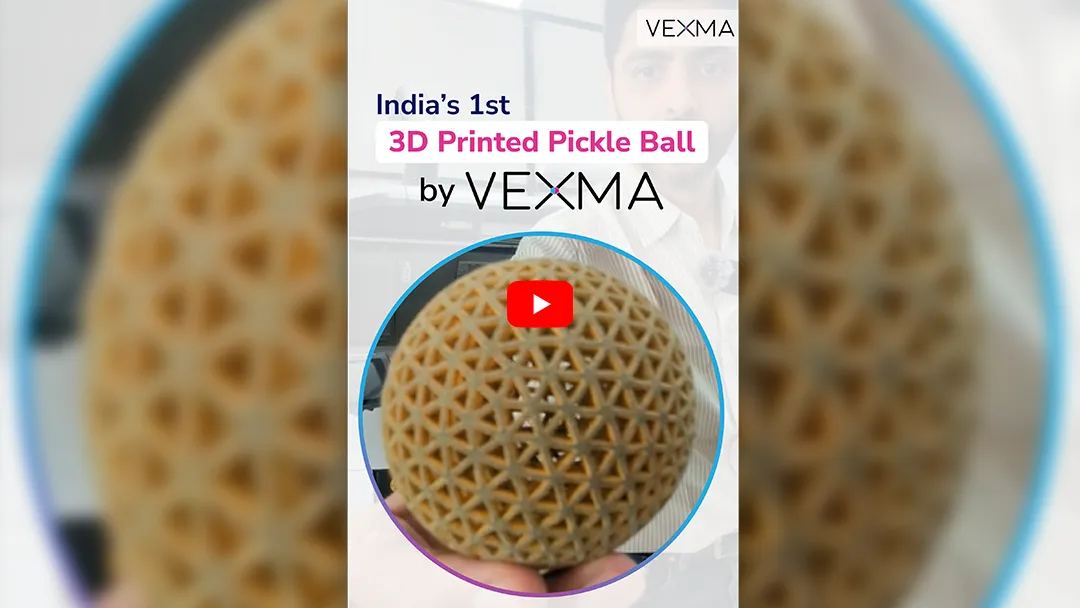

Revolutionizing Pickleball: India’s First 3D-Printed Pickleball by Vexma

For years, the question lingered: Why can’t pickleballs be 3D printed? Skeptics dismissed the idea as impractical, arguing that conventional manufacturing methods were the only viable option. But at Vexma Technologies, we saw things differently. We saw an opportunity to innovate, reduce waste, and revolutionize the game with advanced 3D printing technology.

The Limitations of Traditional Pickleballs

Traditional pickleballs have been manufactured through injection molding or rotational molding, both of which enable mass production. However, these methods come with significant drawbacks that affect the overall playing experience and longevity of the product.

Common Issues with Regular Pickleballs

• Noise Pollution:

A common complaint among communities is the loud “pop” sound generated when a pickleball is struck. Many residential areas have imposed restrictions due to noise concerns, limiting where and when the game can be played.

• Breakage and Durability Issues:

Conventional pickleballs tend to crack, warp, or degrade over time. Uneven material distribution during production can also lead to performance inconsistencies, forcing players to frequently replace their balls.

• Lack of Spin Control:

Traditional pickleballs have a rigid and smooth surface, limiting spin potential. This affects advanced gameplay strategies, as players have less control over the ball’s movement and trajectory.

• Material Wastage:

Traditional production processes result in considerable plastic waste. Excess material is often discarded, raising environmental concerns and reducing overall efficiency.

• Worker Safety Risks:

Manufacturing pickleballs the traditional way involves handling hot, freshly machined products. This increases the risk of burns and injuries for factory workers, making safety an ongoing challenge.The 3D Printing Breakthrough: Lighter, Stronger, Quieter

At Vexma Technologies, we took on this challenge with a clear goal: to reinvent the pickleball, not just replicate it. Using state-of-the-art HP Multi Jet Fusion (MJF) 3D printing technology, we developed a next-generation pickleball that outperforms its traditional counterparts in every way.

• Revolutionary Design:

We engineered the pickleball from the ground up, optimizing its aerodynamics and material composition for enhanced gameplay.

• Unparalleled Durability:

Unlike conventional pickleballs that wear out quickly, our 3D-printed version is virtually indestructible, lasting thousands of games longer and ensuring consistent performance.

• Noiseless Play:

Our innovative material absorbs impact more efficiently, significantly reducing noise levels. Players can now enjoy the game in noise-sensitive areas without restrictions.

• Adjustable Game Speed & Spin Control:

Unlike traditional pickleballs with fixed properties, our design allows players to fine-tune ball speed and apply spin with greater accuracy, catering to different skill levels and playing conditions.Designed for Performance and Sustainability

The integration of HP MJF 3D printing technology allows us to create pickleballs with superior structural integrity and precision. This method minimizes waste, enhances material strength, and ensures consistent quality. The result? A pickleball that’s lighter, stronger, and quieter than ever before.

A Premium Innovation for the Future

Innovation comes at a cost, and our 3D-printed pickleballs are positioned as a premium product. However, the added value is undeniable: extended lifespan, improved player safety, environmental sustainability, and an unmatched playing experience. Are you ready to experience the next generation of pickleball? The future is here, and it’s 3D printed.

Watch our exclusive video showcasing the innovation behind our 3D-printed pickleballs.

👉 Watch Now and experience the revolution!