Design and Tooling:

The process begins with designing the desired product and creating a mold or tooling. The mold can be made of materials like aluminum or steel, depending on the complexity and volume requirements of the project.

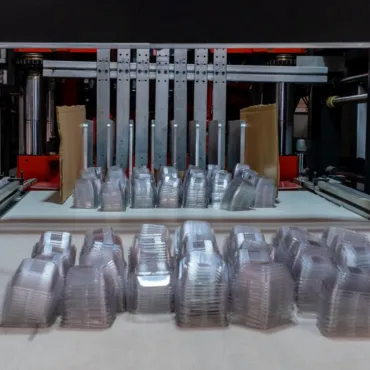

Welcome to Vexma Tech, your go-to destination for top-tier thermoforming 3D printing services. Our commitment to excellence is reflected in our custom thermoforming solutions, offering high-quality prototypes and production parts. Explore the world of precision thermoforming with our advanced techniques and a diverse array of thermoforming materials designed for industrial applications. At Vexma Tech, our thermoforming experts specialize in delivering outstanding results for large-scale projects, prototyping services, and innovative designs. Experience the next level of manufacturing possibilities with our state-of-the-art thermoforming 3D printing services.

Thermoforming is a versatile manufacturing process that finds applications across various industries, offering custom solutions through services like custom thermoforming. This process involves heating a flat sheet of plastic until it becomes pliable, then forming it over a mold to create a specific shape. Thermoforming services cater to diverse needs, providing solutions for both thin and thick gauge thermoforming. Businesses seeking thermoforming services benefit from the ability to create intricately designed plastic components with efficiency and precision.

Whether you're looking for thermoforming services near you or exploring the thermoforming process for specific applications, this method proves instrumental in producing cost-effective and durable products. Thermoforming applications span industries such as packaging, automotive, medical, and consumer goods. Leveraging thermoforming plastic services ensures the production of lightweight, durable, and custom-designed parts, making it a sought-after manufacturing solution.

At Vexma, we leverage our expertise in thermoforming to provide rapid prototyping and product development solutions tailored to our clients' specific needs. Contact us today to discuss how thermoforming can bring your design concepts to life efficiently and cost-effectively.