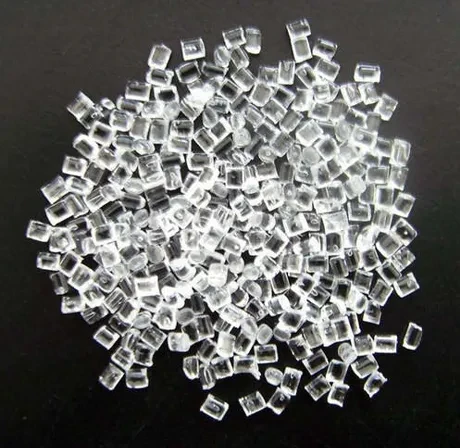

Polycarbonate (PC) is a versatile material widely used in FDM 3D printing due to its exceptional mechanical properties and high-temperature resistance. It finds applications in various industries and offers a range of benefits.

One of the key advantages of polycarbonate is its strength and durability. It exhibits high tensile strength and impact resistance, allowing it to withstand heavy loads and repetitive stress without easily deforming or breaking. This makes it suitable for producing robust and long-lasting parts that can withstand demanding environments.

Polycarbonate is often used to create functional prototypes that require high strength, durability, and heat resistance. It is suitable for testing form, fit, and function of parts before mass production.

Polycarbonate is widely used for producing engineering parts such as gears, bearings, brackets, and housings. Its high impact strength and dimensional stability make it suitable for applications that require structural integrity.

Polycarbonate is utilized in the automotive industry for manufacturing various components, including dashboard parts, interior trim, headlight lenses, and functional prototypes for automotive design and testing.

The aerospace industry benefits from polycarbonate in the production of lightweight yet strong components, such as UAV (Unmanned Aerial Vehicle) parts, drones, brackets, and housings.

Polycarbonate's excellent electrical insulation properties make it suitable for producing enclosures and protective covers for electrical and electronic devices, including circuit boards, switches, and connectors.

Polycarbonate is known for its optical clarity, making it an ideal choice for applications that require transparent or translucent parts, such as light diffusers, lenses, and display covers.

Polycarbonate is used in the manufacturing of medical devices and equipment, including surgical instruments, dental models, orthopedic prototypes, and custom prosthetics.

Polycarbonate is utilized for creating jigs, fixtures, and tooling applications in various industries. Its high strength and temperature resistance make it suitable for demanding industrial environments.

Polycarbonate is employed in the production of outdoor and sporting goods, including protective equipment, helmet visors, sports goggles, and durable equipment components.

Polycarbonate can be used to create architectural models and scaled prototypes due to its ability to produce transparent or translucent parts with high precision.

| Property | Value |

|---|---|

| Tensile Modulus | 2307 MPa |

| Tensile Stress at Yield | (55-75) MPa |

| Elongation at Break | 12.24% |

| Flexural Modulus | 2477 MPa |

| Flexural Strength | 100.4 MPa |

| Glass Transition Temperature (Tg) | 112 - 113 ̊C |

| Impact Strength | 25.1 kJ/m² |

| Heat Deflection Temperature (HDT) | at 0.455 MPa |

| Shrinkage | Ultra-low |