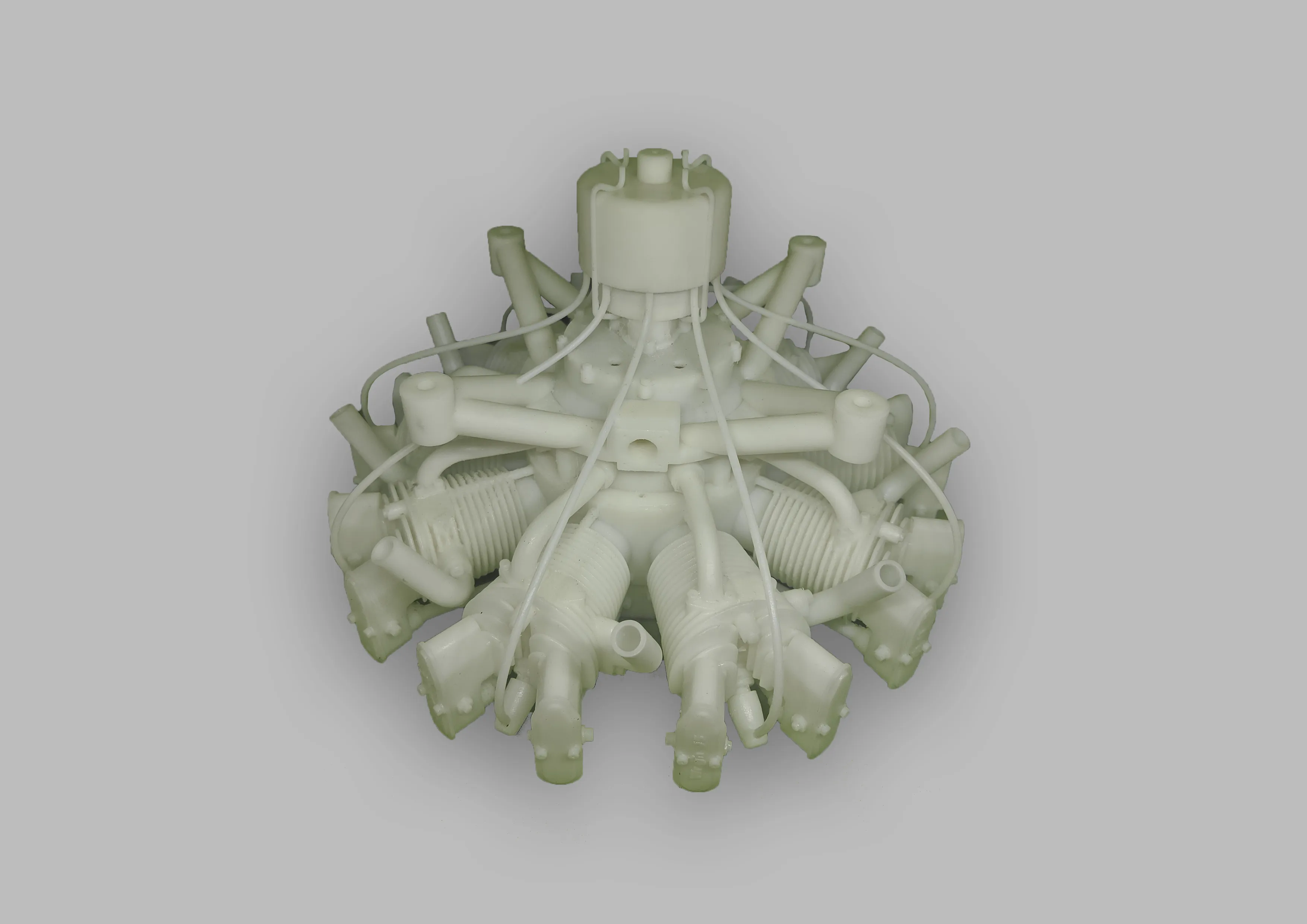

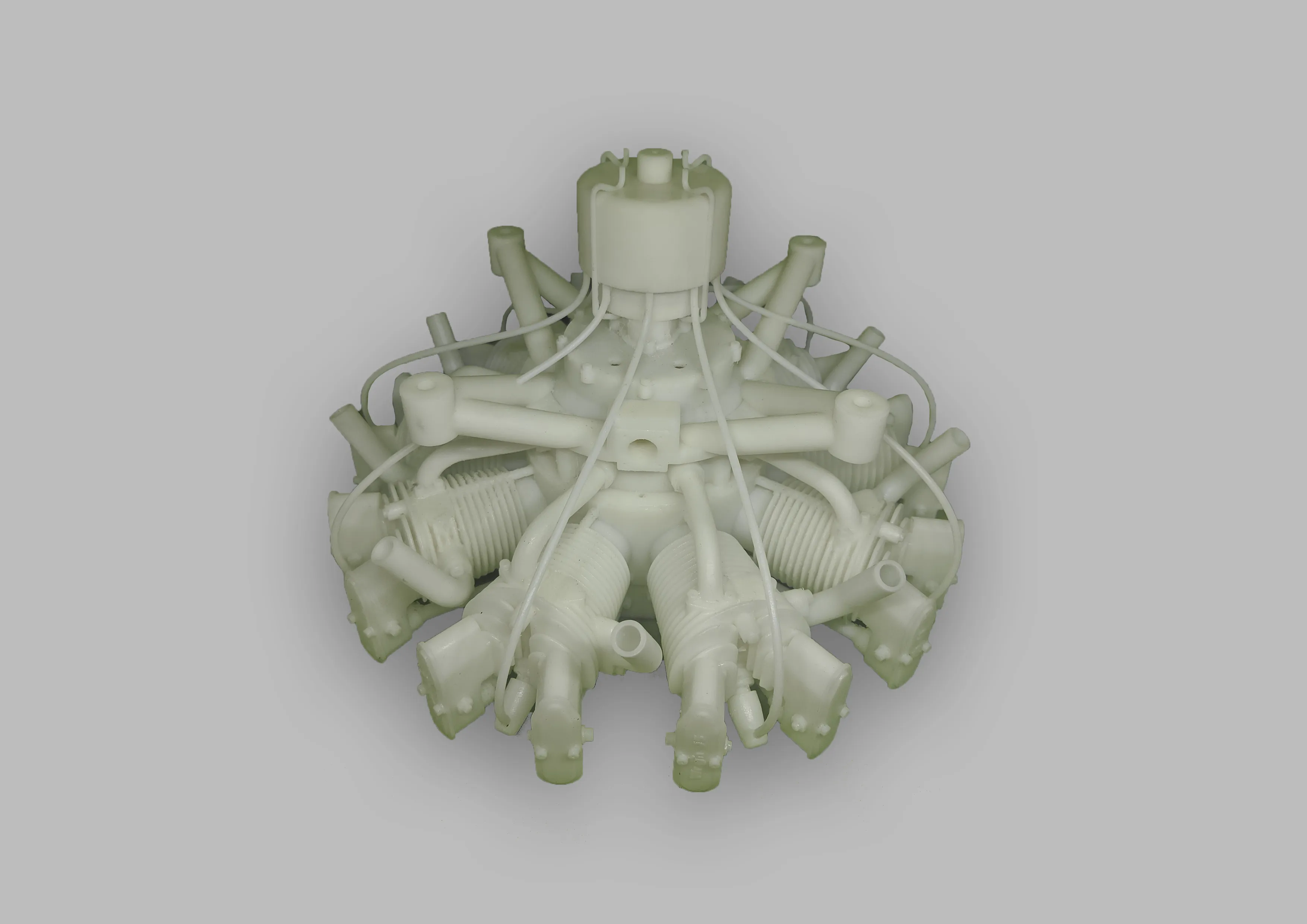

Stereolithography (SLA) is an additive manufacturing technique that employs an ultraviolet (UV) laser to focus on a reservoir of photopolymer resin. Utilizing computer-aided design (CAD) software, the UV laser traces a predetermined design onto the resin's surface. Photopolymers respond to UV light, causing the resin to undergo photochemical solidification, forming one layer of the intended 3D object. This process iterates for each layer until the 3D object is fully fabricated by the SLA 1100 3D Printer.

ZR680 (Accurate & White), ZR710 (Tough & White), ZR820 (High Transparency)

| LASER SYSTEM |

Number of Laser: Sole Laser Type: Diode-pumped solid-state laser Nd:YVO₄ Wavelength: 354.7nm Power: 1000/2000/3000mW |

|---|---|

| RECOATING SYSTEM |

Process: Intelligent positioning - Vacuum press recoat Normal Build: 0.1mm Quick Build: 0.1~0.15mm Precision Build: 0.05~0.1mm |

| OPTICAL & SCANNING |

Beam (diameter@1/e2): 0.10~0.50mm Scanning Galvanometer: High Speed Scanning Galvanometer Parts Scanning Speed: 6.0m/s (recommended) Blank Jumping Speed: 10.0m/s (recommended) Reference Building Speed: 100~230g/h |

| ELEVATOR |

Position repeatability: ±0.01mm Elevator Motor: High Accuracy Servo Motor Benchmark Platform: marble benchmark platform |

| RESIN VAT |

Volume: Approx. 785L@600mm(Z) XY Platform: 1000mm(X)×1000mm(Y) Z Axis: 550mm Max Weight: 120kg@600mm(Z) Resin heated style: Precision resistor heater Photopolymer Resin: ZR680( Accurate & White ) ZR710( Tough & White ) ZR820( High Transparency ) |

| SOFTWARE |

OS: Windows 10 Pro Network: Ethernet, TCP/IP, IEEE802.3 Control Software: iSLA(ZERO 5.0) Date Preparation Software: 3dLayer Data Interface: CLI file, SLC file, STL file |

| INSTALLATION CONDITION |

Power: 200~240VAC AC 50/60Hz, single-phase, 5/17AMPS Ambient Temperature: 20-26ºC Relative Humidity: Less than 40%, non-condensing Size: 1.60m(W)×1.90m(D)×2.30m(H) Weight: Approx. 1700kg |

| WARRANTY |

Laser: 5000 hours or 12 months (whichever comes first) Main Machine: 12 months from installation date |