Preparation:

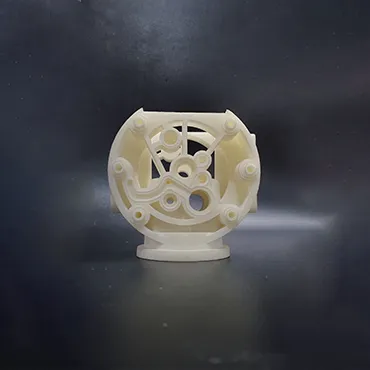

Our process begins with your digital design files, meticulously prepared using state-of-the-art Computer-Aided Design (CAD) software. These files are then sliced into thin layers, generating precise cross-sectional data that guides the printing process.