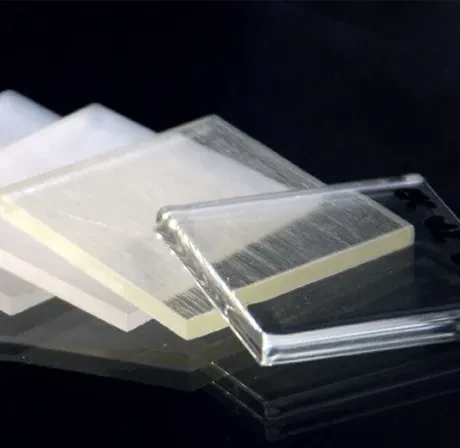

8744 Transparent material is a versatile material used in vacuum casting processes. It is known for its transparency, allowing for the creation of clear and translucent parts. The material is commonly used in applications where visual clarity is essential, such as prototypes, visual models, lighting components, and packaging.

Its transparent properties make it suitable for a wide range of consumer goods, medical devices, automotive components, and design/artistic applications. With its excellent clarity and functionality, 8744 Transparent material offers both aesthetic appeal and functional performance.

The transparent nature of the material makes it suitable for creating prototypes of transparent or translucent products such as lenses, light covers, display cases, and other optical components.

The clarity and transparency of 8744 Transparent material make it ideal for creating visual models used in product presentations, marketing displays, and exhibitions where a clear representation of the final product is required.

The material's transparency allows it to be used for manufacturing light diffusers, lampshades, and other lighting components that require both functionality and aesthetic appeal.

The transparent properties of 8744 Transparent material make it suitable for creating packaging prototypes or small-scale production of transparent containers, bottles, and packaging inserts.

The material can be used to create transparent or translucent parts for various consumer goods such as mobile phone cases, electronic device covers, cosmetic packaging, and household products.

8744 Transparent material is suitable for prototyping or producing transparent medical devices, laboratory equipment, and surgical instruments.

The material can be used to manufacture transparent or translucent components for automotive applications, including headlamp covers, indicator lenses, and interior lighting fixtures.

The transparency and visual appeal of the material make it popular for artistic and design applications, including sculptures, decorative objects, and architectural models.

| Property | Value |

|---|---|

| Hardness | 82 Shore D |

| Tensile Strength | 60 MPa |

| Bending Strength | 80 MPa |

| Izod Impact Strength | 10 kJ/m2 |

| Charpy Impact Strength | 2.5 kJ/m2 |

| Shrinkage | 0.3% |

| Heat Deflection Temperature | 80 °C |

| Heatproof temperature (Tg) | 90 °C |

| Coefficient of thermal expansion | 9×10-5 °C |

| Demold Time | 60 Minutes |