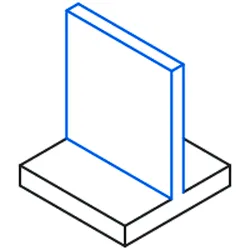

These walls that are connected to other structures on at least two sides (so they have very low likelihood of warping) should be designed at a minimum of 1mm thick.

Walls connected to the rest of the print on one or fewer sides, and have a high probability of becoming detached from the print. These walls must be at least 1.2 mm thick and should be designed with fileted bases to reduce stress concentrations along the joint.

For best results, the wall thickness should be less than 2.5/3.0 mm in order to avoid warping, shrinkage, and curing errors.

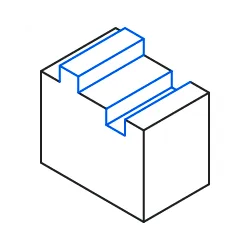

Embossed details are features raised on your model And Engraved details are feature imprinted or recessed below your model. Minimum 1 mm of Line Width and 0.8 mm of Height/Depth is Suggested For 3D printing of it.

If Hole diameter is less than 1.0 mm in Design, holes may close off during printing.

Escaper hole or Perforator is a hole provided to hollow parts for removal of build material . Minimum 4mm Hole diameter is require for successive material removal.

Use 0.5mm clearance between moving parts.

Use 0.2mm clearance for assembly connections.

Use 0.1mm clearance to give a push or snug fit.

To ensure a proper assembly between two parts, it is advisable to include a lip groove feature in both parts. This feature should have a minimum thickness of 1.0 mm, a minimum height of 1.5 mm, and a clearance of 0.2 mm. The lip groove will help to align the parts and provide stability during assembly.

| Tolerance+/- 0.25 to 0.3 % | Of Actual dimension in mm or inch. |

| Tolerance:+/- 0.25 to 0.3mm | For small parts(Less than 100 mm) |

| Tolerance+/- 0.2 to 0.25 % | Of Actual dimension in mm or inch. |

| Tolerance:+/- 0.2 to 0.25 mm | For small parts(Less than 100 mm) |

| Tolerance+/- 0.3 to 0.35 % | Of Actual dimension in mm or inch. |

| Tolerance:+/- 0.3 to 0.35 mm | For small parts(Less than 100 mm) |

| Tolerance+/- 0.3 to 0.35 % | Of Actual dimension in mm or inch. |

| Tolerance:+/- 0.3 to 0.35 mm | For small parts(Less than 100 mm) |

| Tolerance+/- 0.3 to 0.35 % | Of Actual dimension in mm or inch. |

| Tolerance:+/- 0.3 to 0.35 mm | For small parts(Less than 100 mm) |