2D to 3D Conversion:

Conversion of two-dimensional (2D) drawings or designs into three-dimensional (3D) models, allowing for a more realistic and comprehensive representation.

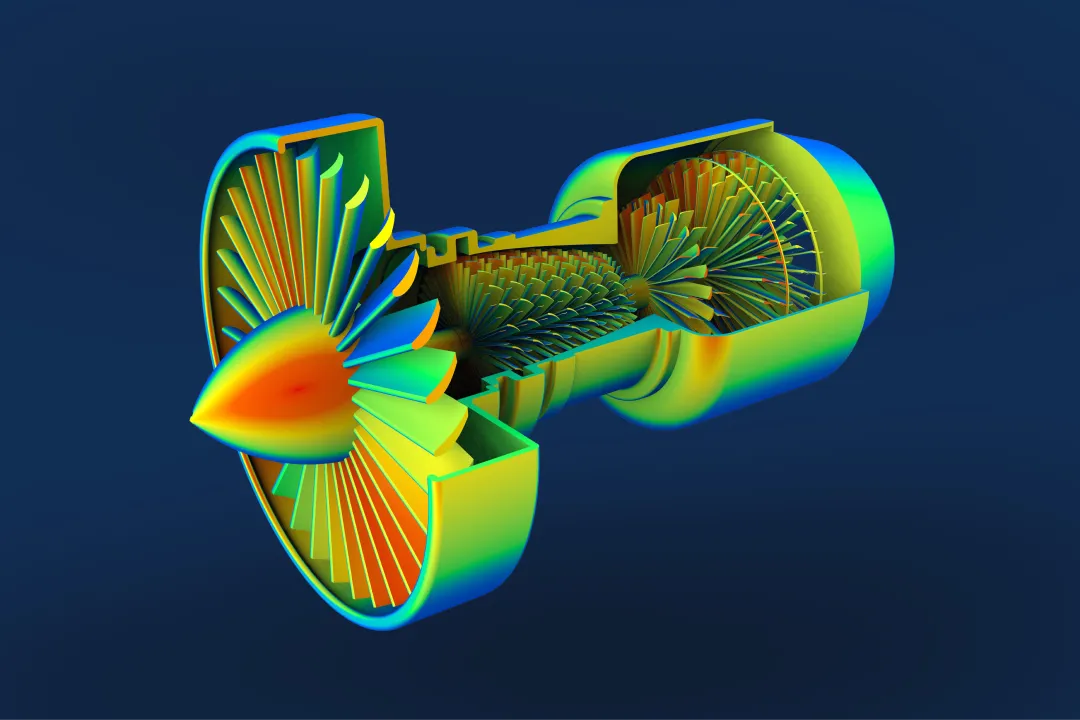

At Vexma Technologies, our expertise lies in Design and Analysis, where we employ state-of-the-art tools like Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) to optimize product performance. We understand the vital importance of structural integrity and fluid flow in product functionality and efficiency.

Our skilled engineers utilize FEA to meticulously assess and enhance the structural integrity of products, ensuring they meet desired performance criteria. By simulating real-world conditions and stresses, we identify potential weak points and iterate on designs to fortify and optimize product strength, all while adhering to 3D printing's inherent capabilities and limitations.